Applications of a bypass system in Chinese cement plants

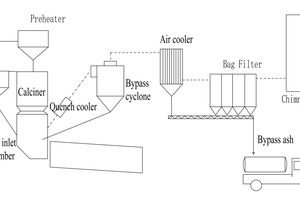

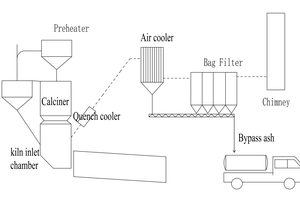

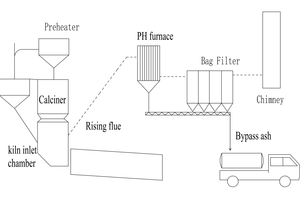

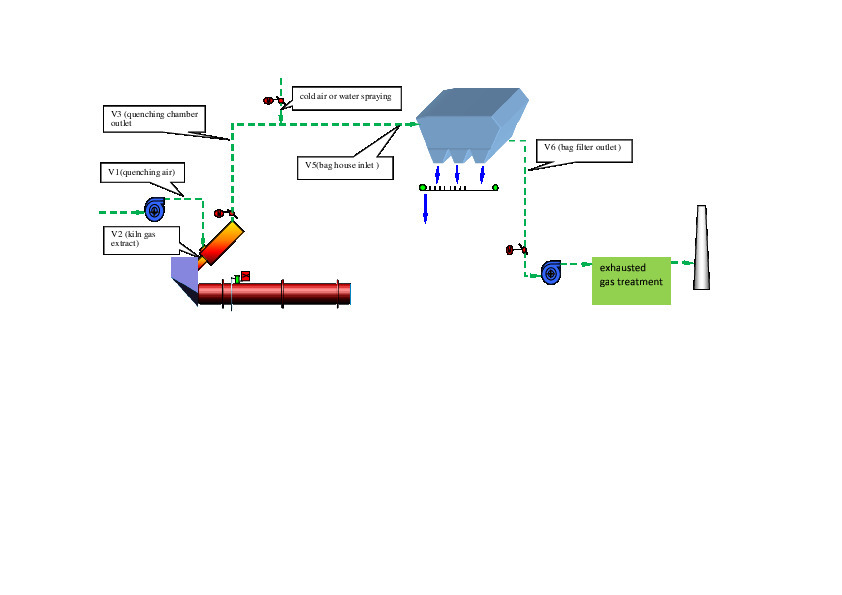

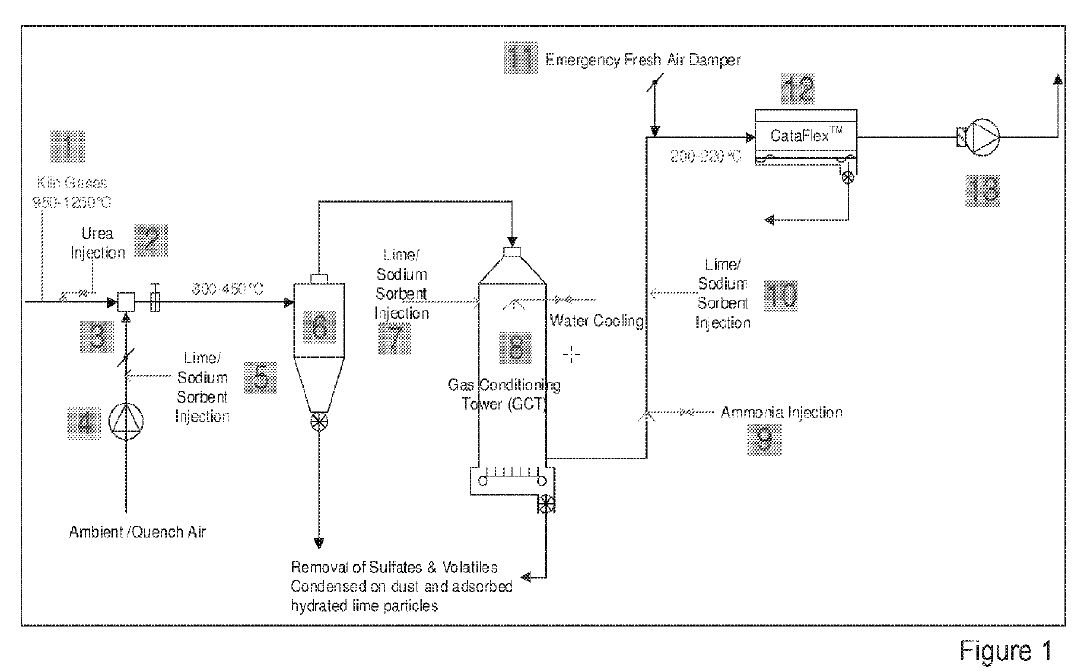

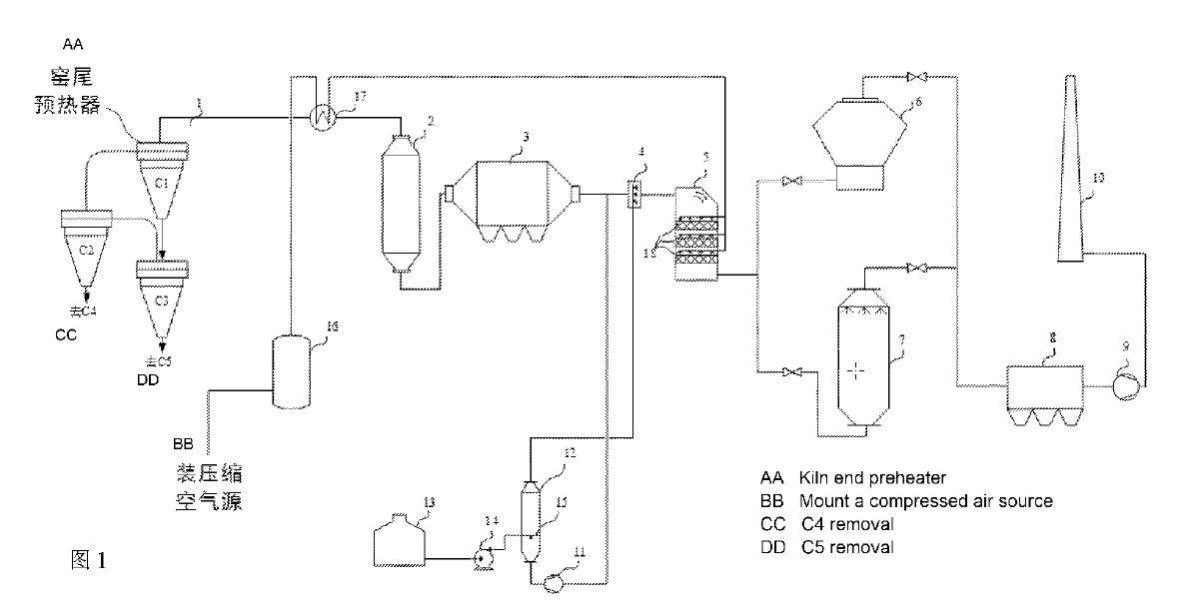

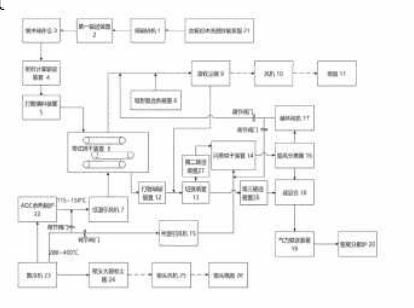

Due to raw fuel, waste disposal, or using of alternative fuel and other reasons, chlorine and other harmful elements in the cement kiln circulate and accumulate in the burning system, resulting in serious scaling and blocking, affecting the stable operation of the burning system and clinker quality. The author introduces several typical applications of bypass system in Chinese cement plants to address these issues.

1 Introduction

In cement production, harmful elements such as potassium, sodium, chlorine, and sulfur are recycled and enriched in the burning system, which can cause serious impacts, including severe scaling and blockage in the kiln tail smoke chamber, feeding slope, final stage cyclone cone, and other parts. It also affects the stable operation of the burning system and the quality of the clinker [1]. With the rapid development of the cement industry, the resources of raw materials are becoming increasingly scarce, and cement production has to adapt to raw fuels with high volatile harmful...