Joined forces for catalytic filter bag technology

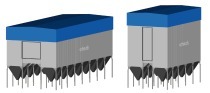

Haldor Topsoe A/S and FLSmidth A/S, Kgs. Lyngby resp. Valby/both Denmark have signed a cooperation agreement that marks the beginning of a joined global effort to commercialize a newly developed unique catalytic filter bag technology. The product will carry the brand name EnviroTexTM catalytic filter bags and is capable of removing dust, volatile organic compounds and nitrogen oxides in one integrated and cost-effective process. Over the past four years the two parties have been working closely together on developing the technology. As part of this effort the product has been thoroughly tested and proven efficient for several industrial applications. The key differentiating factor about the patent-pending catalytic filter bags lies in the fact that EnviroTexTM consists of three layers of filter fabric. Each layer contains a tailored catalyst optimized for the removal of specific kinds of compounds from the off-gas that passes through it.

As part of the agreement between FLSmidth and Topsoe, the new product will be manufactured at FLSmidth’s bag production facilities in Georgia, USA. The high quality filter bags will then be catalyzed and assembled at Topsoe’s catalyst production site in Houston, Texas. In fact Topsoe’s production site will be expanded with an entirely new production line dedicated to the production of EnviroTexTM catalytic filter bags. The goal is to complete construction of this facility by end-2015.

//www.flsmidth.com" target="_blank" >www.flsmidth.com:www.flsmidth.com

//www.topsoe.com" target="_blank" >www.topsoe.com:www.topsoe.com