Korfez Eng. – “Your mill our challenge”

The Korfez Eng. sales office located in Neubeckum/Germany is a partner for solution-oriented and technical consultancy services and delivery of high-alloy wear- and heat resistant steel castings for the cement and mining industries.

The main products include spare parts for crushers, cyclone preheaters, cement kilns, clinker coolers, vertical and ball mills.

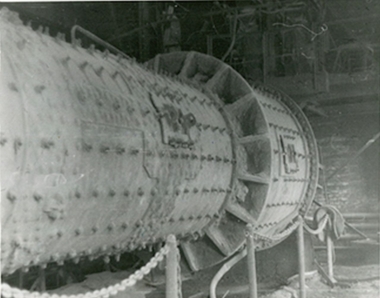

The Turkish partner, the foundry Körfez Döküm, situated near Istanbul/Turkey, has been producing steel castings from 0.500 kg to 6000 kg on a built-up area of 12 000 m² since 1988. With the help of more than 300 employees a capacity of approx. 10 000–12 000 t/a can be achieved.

By now the export share of Korfez Eng. and Körfez Döküm Sanayi ve Ticaret A.S. is about 75 % in more than 50 countries on all continents.

Providing comprehensive support to the full satisfaction of the customers has the highest priority. To build long-term business relationships, the company acts as an interface and arranges for clear responsibilities and a coordinated customer contact while providing assistance in all sales activities worldwide.

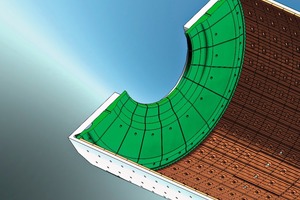

From 2011 onwards, Korfez Eng. has increasingly concentrated on the engineering and manufacturing of system components, primarily mill shell linings and mill diaphragms for ball mills used in the cement and mining industries.

Korfez Eng. conceives and designs ball mill systems tailored to the customers’ needs. For optimum results each requirement is considered individually, with customer expectations and needs always taking center stage.