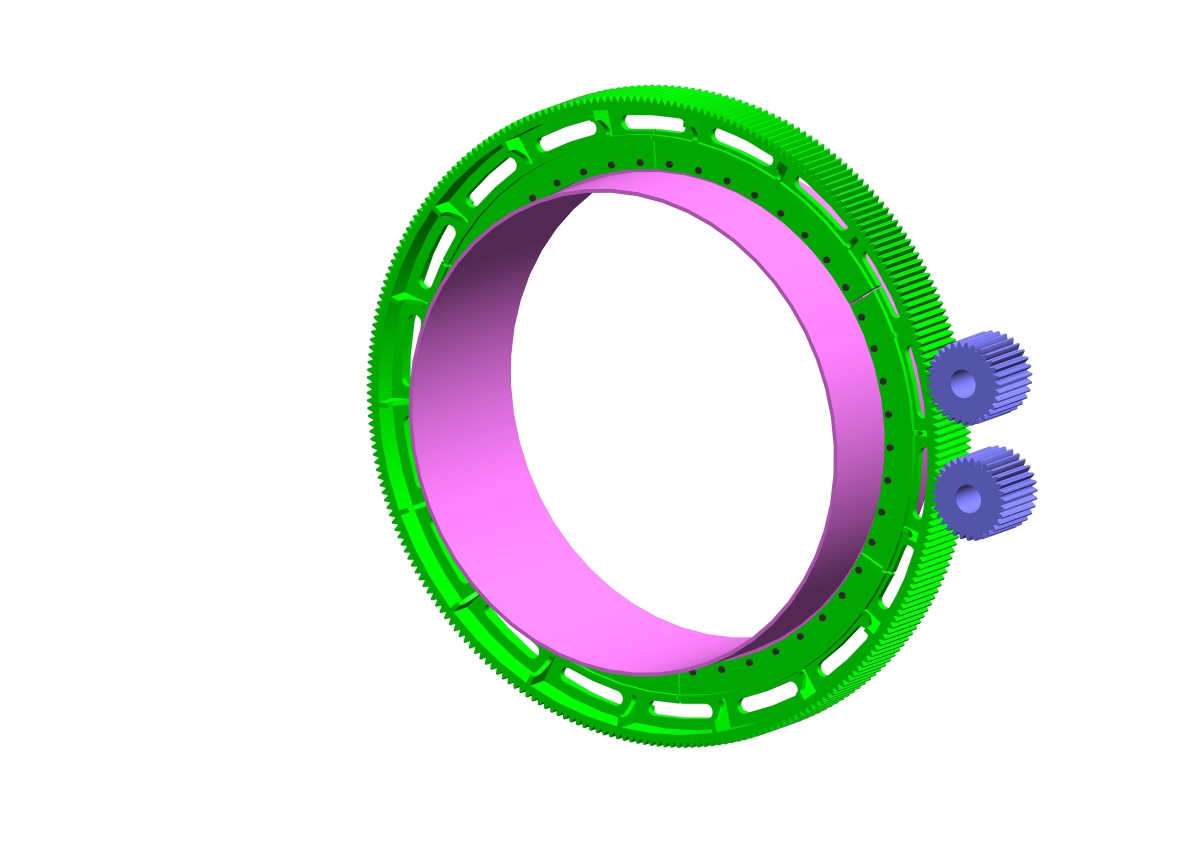

Tube mill drive systems – a review

A review of the available literature on the development of tube mill drives is presented in this paper. This presentation includes the motor selection, a mill drive analysis, a failure analysis, the lubrication, the vibration measurement and the finite element analysis, covering strain and fatigue design and a brief write-up on materials and inspection.

1 Introduction

In cement production, tube mills with multi-chambers are traditionally used in either open or closed circuit operations. The process of cement grinding basically includes a grinding mill surrounded by a hoppers feeding system, dust filters, material transport, lifting equipment and cement storage silos for further dispatch in bulk and bag processing.

2 Motor selection

The ball mill is the largest single power consumer in a cement plant. Schachter and Ruesch [1] report that in the process of selecting a suitable motor, there are several issues to consider that, for the purpose of...