Lafarge Zementwerke GmbH relies on the Beumer single-source solution

For an economical and sustainable operation, the Austrian plant Retznei of Lafarge Zementwerke GmbH relies on alternative fuels and raw materials to ignite the new calciner. In order to transport, store and dose the kiln-ready material efficiently, the manufacturer awarded Beumer Group with the development of an individual single-source solution. The core of this system solution is a U-shape Conveyor: the conveying system ensures an environmentally safe, dust-free and low-energy transport of the pre-processed waste.

In Austrian Styria, the small village of Retznei lies directly on the Mur river. Many inhabitants in this area make a living from growing grapes, fruit, pumpkins and beans. However, the most important employer does not originate from agriculture but from cement production: Lafarge Zementwerke GmbH, a company of LafargeHolcim headquartered in Rapperswil-Jona in Switzerland. “Cement has been produced in Retznei since 1908,” says Franz Wratschko of Lafarge Zementwerke, who is an investment manager at the Retznei plant. If, at that time, the first owner of the plant, the Ehrenhausener Portlandzementwerke, had a yearly production reaching between 4000 and 4500 wagons, as stated in an old report, nowadays the yearly production is approx. 625 000 t. “Our plant is known as an absolute economic motor for this region,” says Franz Wratschko.

Lafarge Zementwerke places particular value on high-quality products, but also on a sustainable, energy-efficient and environmentally friendly manufacturing. In order to reduce greenhouse gas emissions and lower production costs, the company focused more on the use of alternative fuels for firing the new calciner. Instead of coal and oil, only pre-processed and selected recyclable materials of waste disposal are fed into the kiln. This is already a low calorie material with a calorific value of approx. 14000 kJ/kg, which represents a practical, cost-effective and environmentally friendly alternative to the conventional deposition and combustion process. “However, the thermal exploitation of these materials in cement plants offers further advantages,” explains Franz Wratschko. “The temperatures of approx. 2200 to 2400 °C prevailing in the rotary kiln make sure that the organic pollutants are completely destroyed. During the combustion process, ashes are completely eliminated, and the combustion residues are incorporated in the cement clinker.” The manufacturer awarded Beumer Group the installation of a conveyor line, which feeds the material into the calciner at a capacity of 15 t/h.

Economical all along the line

In order to support producers of cement in the alternative fuels and raw materials field (AFR), Beumer Group has set up its own business segment dedicated to AFR systems. “Our know-how and tailor-made systems permit us to offer optimum support to our customers”, says Jan Tuma, Chief Sales Officer at Beumer Group in the Czech Republic. “We have years of experience and we always consider our customers’ specifications.” With this capability, the system provider is able to supply and install the whole chain from the acceptance and unloading of the delivery vehicle, up to the storing, conveying and feeding process of the solid alternative fuels for the specific user. The customer receives everything from one source, thus having a unique contact.

The alternative fuels and raw materials have to fulfil specific quality requirements. Only pre-processed waste with a minimum calorific value of 22 000 kJ/kg and correspondingly low heavy-metal contents may for example be used. The material is supplied by Geocycle. The waste disposal service provider is part of the LafargeHolcim Group and pre-processes construction and mineral production waste for clinker production in the recycling centre of Retznei. “The material we receive has a particle size of 120 x 120 x 20 mm and a density of 100 kg/m3,” says Jan Tuma. “The moisture content amounts to 30 %.”

Smooth running

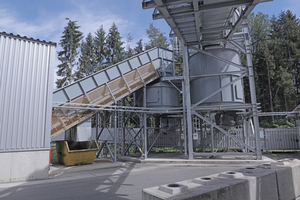

The kiln-ready material is supplied by Geocycle in moving-floor trailers. The hydraulically controlled moving floor moves the load outwards on the conveying system. “All conveying systems supplied and the accompanying equipment are intertwined to ensure steady fuel feeding,” explains Jan Tuma. “In this regard, we have installed our unloading station BG OptiBulk.” A chain belt conveyor with a length of 15 m and a belt width of 2.8 m conveys the material to this unloading station at a height of 6.6 m. The BG OptiBulk is equipped with a special housing, which protects the environment from dust escape and the material from environmental stress. “This station enables unloading of up to 150 m3 of fuel per hour,” says the Beumer expert. The material, which is delivered by trucks, falls from the unloading station into the BG OptiFeed screw weigh feeder in a container of 20 m3. A conveying system transports further combustible material of the waste disposal service provider Geocycle to a second BG OptiFeed in a container of 50 m3.

“In order to enable a continuous controlled feeding of the material, we have installed one BG OptiFeed for each material flow,” explains Jan Tuma. The screw conveyors with weighing cells are suitable for completely different materials – that means that they are ideal for the continuous feeding of alternative fuel or raw materials. Since the screw conveyors are positioned on the weighing cells, it is always possible to see how much material is extracted. The feeding speed to the following conveying elements amounts to up to 15 t/h. The system is dimensioned for bulk densities reaching between 0.08 and 0.15 t/m3, the regulation ratio is 1:20 and the maximum feeding accuracy between one and two percent. In addition, the completely closed screw weigh feeder is protected against dust. “Thus we can feed the downstream U-shaped conveyor with up to 15 t material per hour,” says Jan Tuma.

Reliable u-shaped transport

The U-shape Conveyor is the key component of the entire system. “We evaluated and considered different variants of mechanical conveying systems,” reports the Beumer expert. “Finally we decided on this conveying solution. U-shape Conveyors can be simply integrated and are also suitable for long distances and rough terrain as well as horizontal and vertical curves. The material conveyed is protected against external influences such as wind, rain or snow and the environment against possible material loss. This conveying solution is suitable for coarse but also for very fine material. The system in Retznei has a diameter of 250 mm, a conveying length of 253 m and navigates at a speed of one metre per second a height of 32 m with a maximum inclination of more than 20 °. At the feeding point, the U-shape Conveyor is open as a traditional belt conveyor,” explains Jan Tuma. “A special idler configuration brings the belt in a u-shape.” This way the bulk material reaches the discharge station. An idler configuration similar to that for the shaping is used for opening the belt. Compared to the Pipe Conveyor, the U-shape conveyors have, among other things, considerably higher feeding rates because a smaller belt is used.

The U-shape Conveyor transfers the material to a double discharge screw conveyor of the BG OptiLock constructions series. The airlock of this system solution protects the pyroprocess from the infiltrated air from outside, which can arise in the combustion process. The BG OptiLock is also equipped with weighing cells. Therefore, the owner always has an overview of the actual material load. The discharge screw conveyor transfers the bulk material continuously on a screw conveyor, which feeds the calciner. As the material can catch fire, the system provider has designed all supplied systems according to the ATEX directive for the zones 21 and 22.

“We are very satisfied with this single-source system,” states Franz Wratschko of Lafarge Zementwerke GmbH. “The conveying systems and the accompanying equipment are intertwined to ensure steady fuel feeding.” Beumer Group could demonstrate their substantial competence with regard to the handling of alternative fuels in the cement industry and their ability to support their customers efficiently – all within a short period of time: The contract for this order was signed in May 2018 and in January 2019 the system was put into operation.