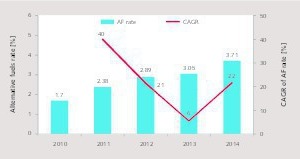

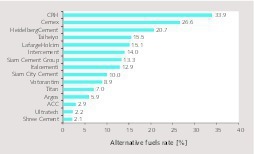

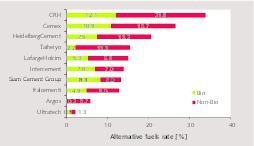

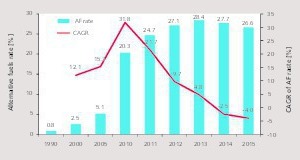

Latest trends in alternative fuels

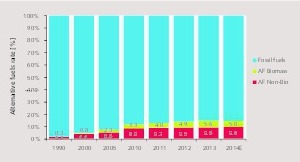

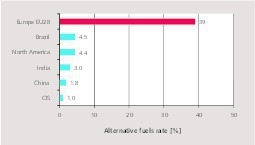

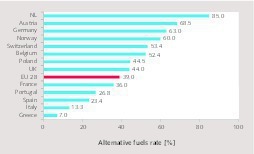

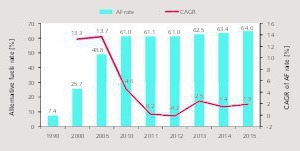

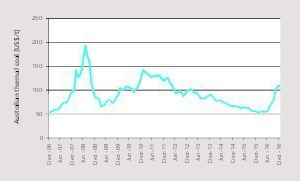

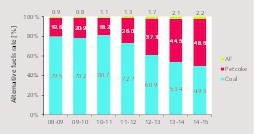

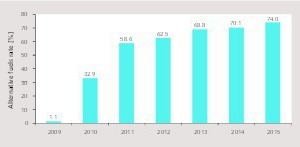

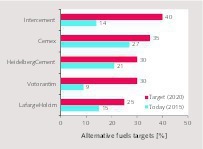

After some years of small increases or even stagnation due to falling energy prices, the use of alternative fuels as a substitute for conventional fuels in the cement industry is on the rise again. This market review will deal with the major trends, while highlighting country trends, cement producer trends, technical trends, as well as market drivers and barriers.

1 Introduction

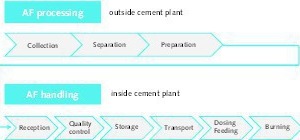

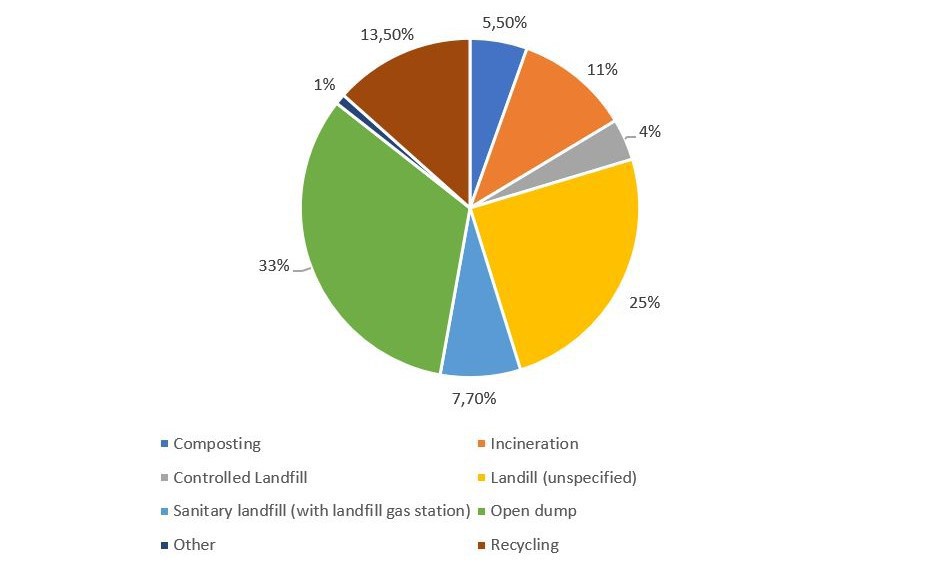

Co-processing is the use of waste fuels as a source of energy and raw material [1]. This has already been practiced in the cement industry for a couple of decades. The clinker burning process offers excellent opportunities for the safe and sound recovery of a wide variety of AFR (alternative fuels and raw materials). The typical energy recovery of, for example, fluff is 86 % with 6 % Si, 4 % Ca and 4 % Al+Fe material recovery, and virtually no additional waste is produced. Co-processing saves resources and reduces green gas emissions, but the main advantage is more and more seen...