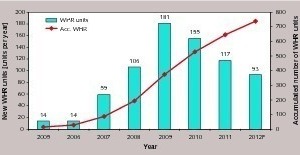

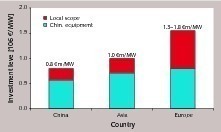

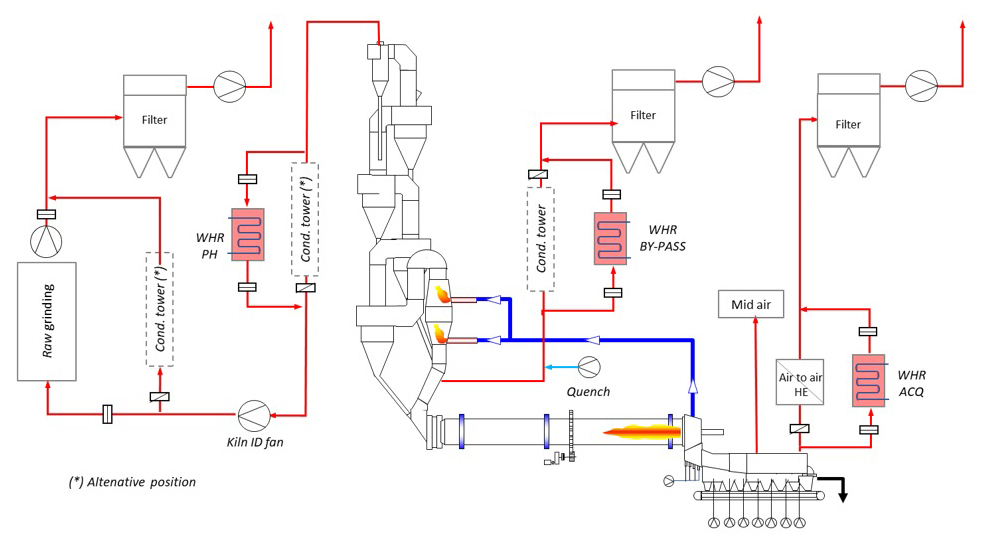

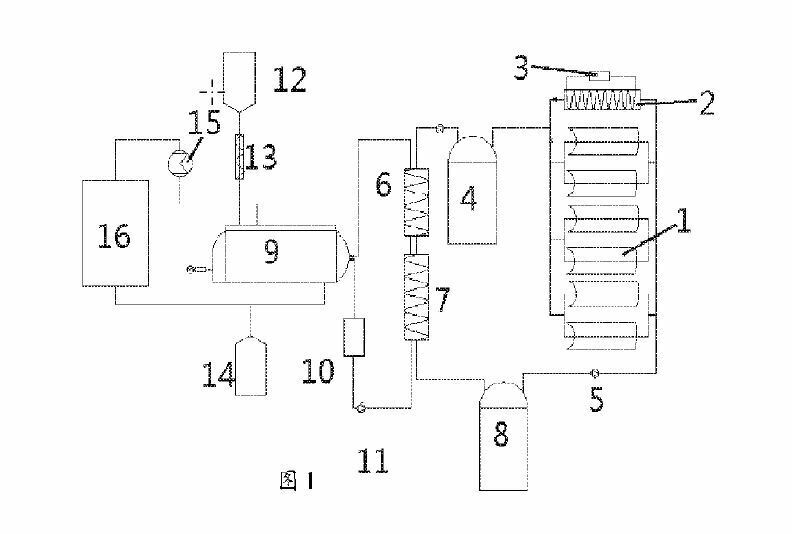

The number of installed systems for generating electrical power from waste heat has increased worldwide from 525 in 2009 to 865 in 2012. The number of non-conventional processes has also risen noticeably. However, most users are still giving preference to the conventional steam turbine systems. This market report focuses on the technical parameters, because these are often misjudged. In addition, the market development is described with an outline of the WHR systems currently in operation, and three case histories are introduced.

1 Introduction

In recent years, power generation from waste heat...

TEXT Dr. Joachim Harder, OneStone Consulting S.L., Barcelona/Spain