Long reach

Conveying systems form the backbone of efficient production processes. Conveyor belts and conveying equipment are thus a central influencing factor for companies‘ competitiveness. To maintain their peak performance over the long term, regular maintenance is a must.

1 Flexible system solutions for companies

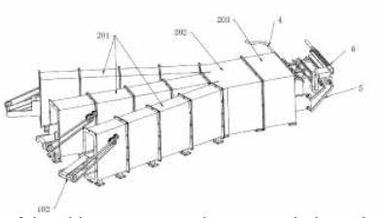

For conveyor systems used for raw material extraction, the belt and other components must be changed after a certain operating time. Conveyor systems used in opencast mining are exposed to particularly difficult conditions that affect the structure of the belt and thus limit its life expectancy. On the other hand, the extraction of natural resources, particularly in regions that are geographically exposed, has again become very lucrative. High demand from the industries of economically emerging nations, the resulting scarcity of certain resources and their increase in price are making conveying projects that were only a few years ago classed as unprofitable again attractive. In this case, the materials and equipment used are often exposed to extreme temperatures, higher levels of insolation or high humidity levels. With the help of specialists who have the necessary know-how and knowledge, professional maintenance and the trouble-free exchange of worn components such as conveyor belts, drive and redirector drums and carrier rollers can be guaranteed. Even large conveyor belts that run round the clock, are several kilometers long, or carry especially heavy materials, can be successfully exchanged using proven techniques and innovative approaches (Fig. 3).

2 Replacing the heaviest-duty conveyor belt in the world

To keep the production loss as low as possible, a REMA TIP TOP team of experts created a sophisticated technical solution that permitted both belts to be simultaneously exchanged in parallel with the running operation (Fig. 4). Both old belts were replaced by the new ones directly on site. In the first phase, half of the belt length was vulcanized together for each belt. The kilometer-long belt loops made in this way were positioned in pits made for this purpose and later attached to the existing belt. This process was then repeated for each second half of the belt.

A smooth sequence of events is decisive, particularly in critical phases such as this that directly affect the production operation. To ensure this, and taking into account the heavy weight of around 44 t per belt length and the length of the splice, 13 people were permanently assigned to each belt. By having the trained personnel operate in two shifts, and through the high degree of work efficiency and the use of state-of-the-art materials and tools, both conveyor belts – a total length of 23 km – could be simultaneously and successfully exchanged (Fig. 5).

In addition to the high requirements regarding quality and work protection, the efficiency of the work processes was also right at the top of the priority lists for this project. This meant that it was necessary to use tools and machines that were state of the art, above all for time-consuming work such as the rubbing down of cover plates, the stripping and brushing off the steelcord or the filling of steelcord interstices. Only the assembly of the vulcanization process – with 10 heating plates and 48 beams – could not be accelerated through the use of machines. Here the fitters were actually even faster than using a crane.