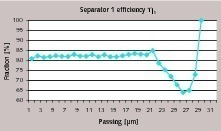

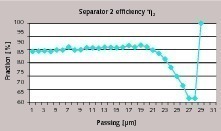

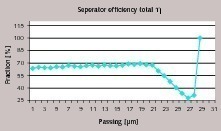

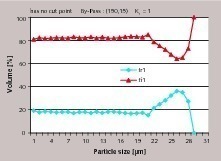

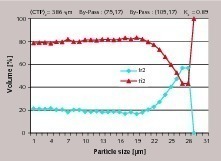

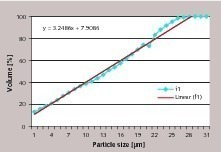

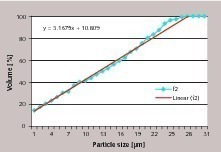

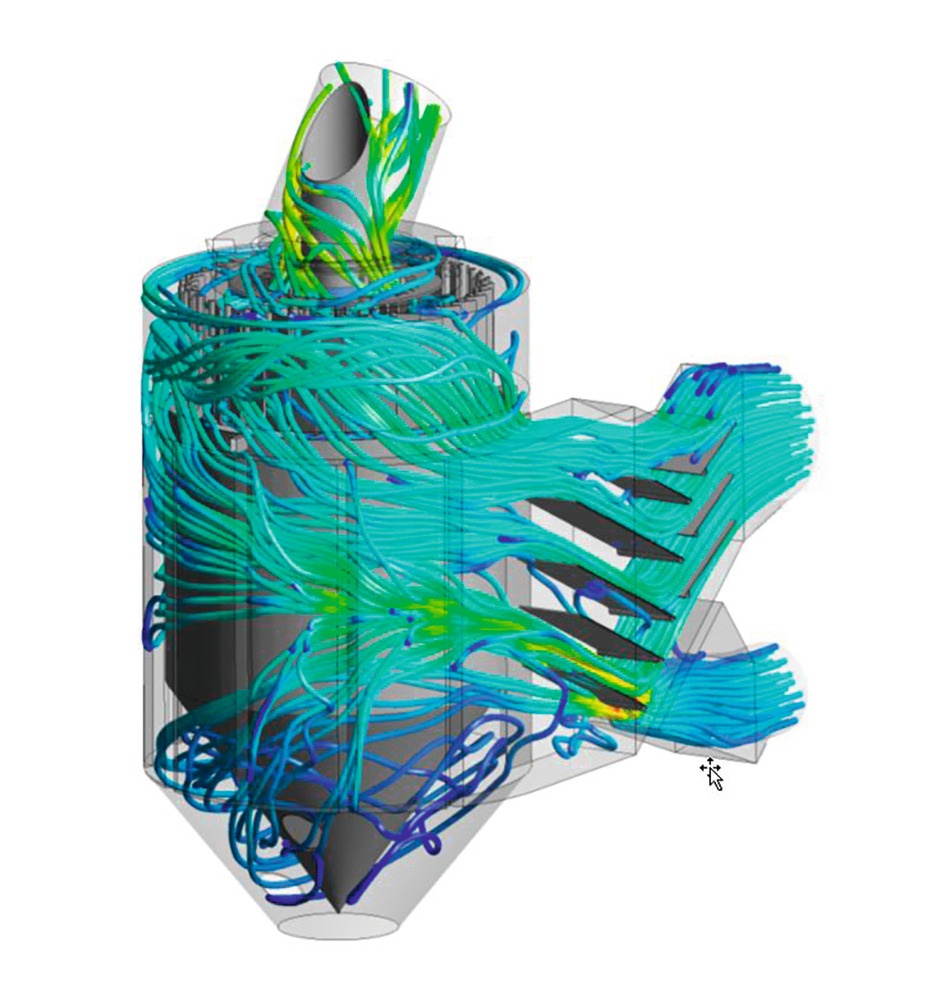

Mathematical separator performance evaluation

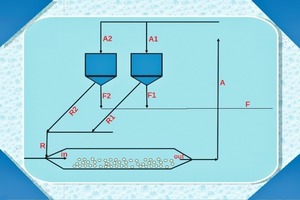

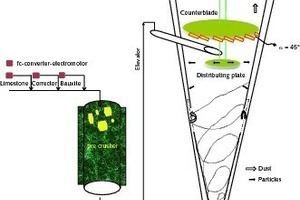

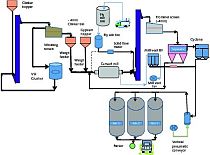

Separators in the cement industry have the task of separating coarse from fine material, and it is worthwhile to fully understand the function of separators in raw and cement mills. Consequent troubleshooting, the elimination of technical barriers and optimum processing will result in an increase in the final product of the mill.

1 Introduction

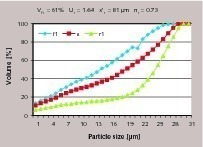

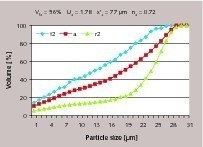

For the stable operation of a cement mill it is essential to know its...