Method and plant for denitrifying bypass gases in a multi-stage system of mixing chambers in a plant for producing cement clinker

(22) 25.01.2019

(43) 23.05.2019

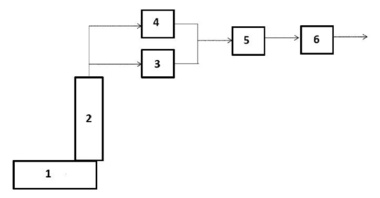

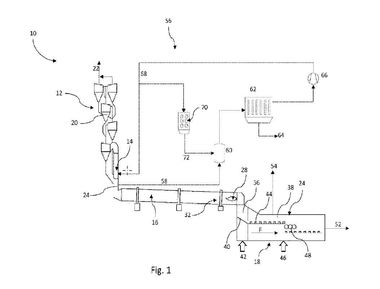

(57) A method and a corresponding plant for denitrifying bypass exhaust gases in a cement clinker production plant. Raw meal is sintered in a rotary kiln and deacidified in a calciner. A rotary kiln inlet chamber is connected to the calciner directly or by a riser duct. Bypass exhaust gas is drawn off near the inlet chamber. This exhaust gas is guided into a first mixing chamber, in which the exhaust gas is cooled to between 800 and 950° C., then the exhaust gas is guided through a reaction pipeline segment, wherein the dwell time is between 0.5 and 3 seconds and ammonia, aqueous ammonia solution, or ammonia-releasing substances are injected for denitrification. Then the exhaust gas is guided into a second mixing chamber, in which the exhaust gas is cooled to between 150 to 250° C. Then the exhaust gas is guided to a filter for dust removal.

(71) KHD Humboldt Wedag GmbH, Koeln (DE)