New activities in Russia

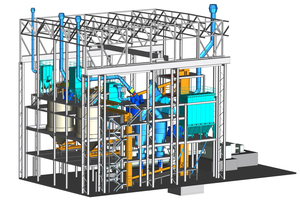

Intercem has been awarded the contract to supply a high-efficiency separator ICS 143, as well as the associated plant aggregates for a new cement plant in Russia. The high-efficiency separator, an in-house development manufactured in the company workshop, has a capacity of 115 t/h at 3000 cm2/g acc. to Blaine and a total output of 258 t/h. The volume flow classifying air is 143000 m3/h. The scope of supply also includes the engineering for the complete grinding plant as well as the supervision of the assembly and the commissioning of the components included in the delivery.

//www.intercem.de" target="_blank" >www.intercem.de:www.intercem.de