Optimisation of the secondary fuel dosing system

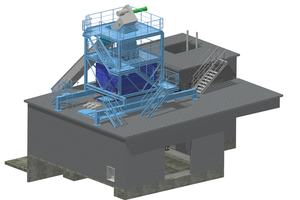

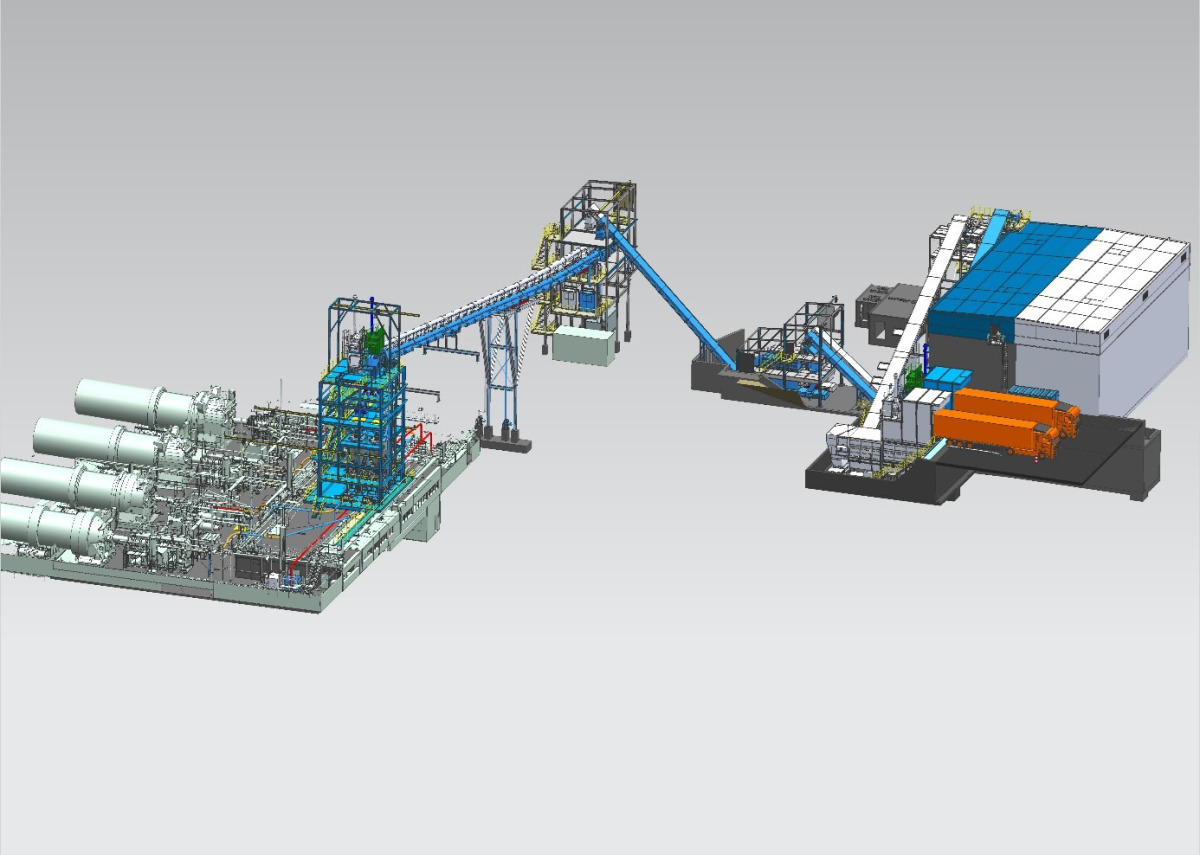

In a German cement plant the secondary fuel dosing system had to be optimized and Intercem was commissioned to do so. The scope of delivery includes the following items: Disassembly on site, refurbishment of the trough chain conveyors still to be used, construction of a new bunker and installation of the refurbished screws. This combination of new and refurbished parts ensures that the costs for the customer can be kept as low as possible. The engineering as well as the assembly of the new components and the provision of the necessary cranes, hoists and other equipment are also included.

//www.intercem.de" target="_blank" >www.intercem.de:www.intercem.de