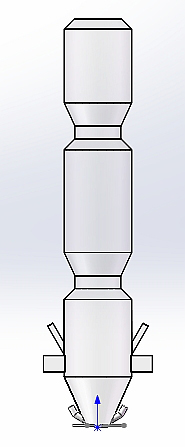

Recent trends in calciner design

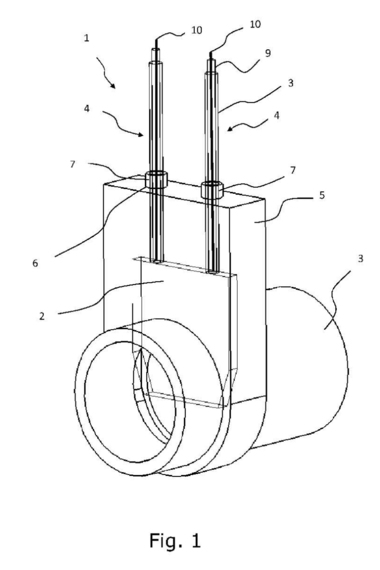

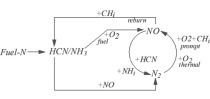

Summary: In this paper, a brief review of the calciner flow stratification and its effect on both meal calcination levels and particle burnout is presented, citing the examples of selected calciners, together with low CAPEX methods to get the required combustion in existing calciners without having to increase their size. A step which is highly recommended for all existing plants, any further calciner throughput may be sought through the incorporation of a precombustion chamber, specially if larger size and higher density alternative fuels are to be used, as compared with extending the equivalent residence time in the calciner. However, as far as the current trend of building “bigger” calciners is concerned, which would allow residence times of 8-10 seconds, these are not really necessary if, in the design, more attention is given to the early mixing and combustion of the AFR, coal, petcoke, tertiary air and kiln gases.

1 Introduction

The cement industry has become significantly more energy efficient during the last 30 years with new plants having the standard features of cyclone preheater systems with precalciner technology, short kilns burning 35 to 45 % of the total fuels as well as incorporating multi-stage clinker cooling systems. Further improvements through the use of alternative fuels and raw materials (AFR) have led to cost reduction measures, as modifications to the existing plants are sought and new plants are being built making provision for AFR. The variation in the availability and properties of...