Reburning: How to reduce NOx emissions in different types of inline calciners

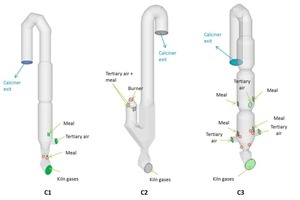

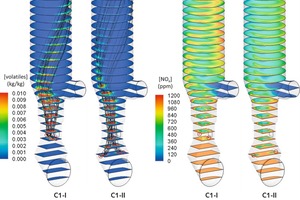

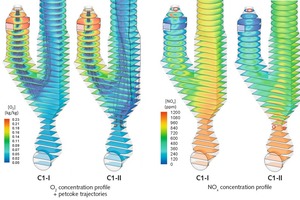

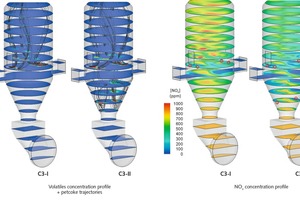

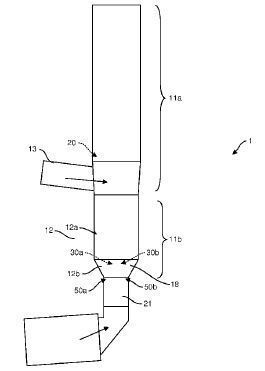

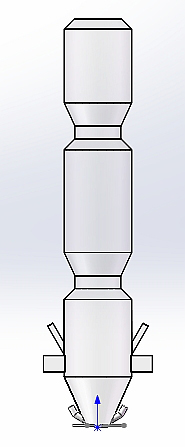

In this paper, three industrial in-line calciner configurations are modelled and simulated to study the NOx formation together with proposed design modifications to allow for an optimized reburning of the formed NOx. Considerable reduction on NOx emissions was achieved in the three studied cases, upon implementation of the proposed modifications, by creating localized zones with high temperatures and volatiles concentration and low oxygen concentration. The studied cases show that, even if the original calciner design does not meet the ideal conditions for NOx reduction, it is possible to relocate the burners or add extra burners in the riser duct to create the appropriate reburning conditions and achieve the desired targets of NOx reduction.

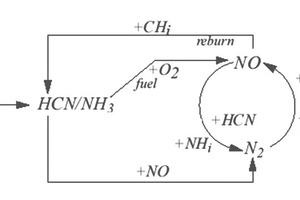

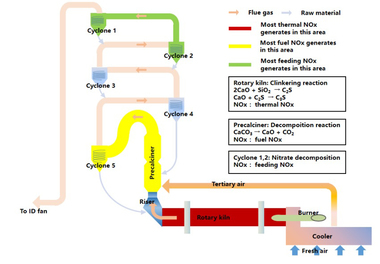

Several techniques can be used to reduce NOx emissions in the cement industry. Primary measures consist in optimization of the kiln and calciner combustion and should be comprehensively studied and implemented before the implementation of secondary measures, which consist mainly of treatment of the exhaust gases (SNCR and SCR) and necessarily present higher operational costs. One of the best options for reducing NOx relies on the calciner optimization by means of reburning. This technique can reduce the NOx formation in the calciner and create conditions to reduce, within the calciner, the NOx...