Refractory company in Taiwan decides to use mixing technology from Eirich

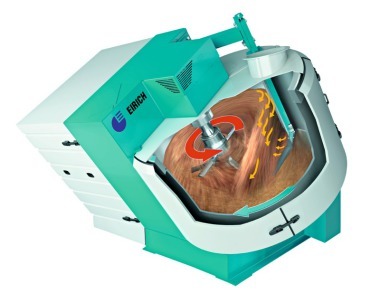

There are a large number of companies worldwide that manufacture refractory products and offer kiln linings, e.g. for the production of aluminum, iron and steel, glass, ceramics or cement. Standards distinguish between “shaped products” (bricks) and “unshaped products” (which include castables and also ramming mixes or plastic mixes). Brick production has been steadily declining for decades, while unshaped refractory mixes production is on the rise. And the mixes are becoming more and more demanding. For the preparation of dry mixes based on alumina as well as magnesia, Hsin Lian Hsin Enterprise Co., Ltd, Taiwan, has chosen the Eirich mixing technology.

While refractory bricks go a long way in production (mixing, shaping, heat treatment), unshaped mixes are ready for shipment after mixing. Mixers for the refractory industry must, on the one hand, mix well, and on the other hand, cope with hard raw materials (such as corundum or silicon carbide) without excessive wear. In brick production, the industry has been relying on the Eirich mixer since 1930, which - designed with a rotating pan - today in sizes up to 3 m³ requires only a single moving mixing tool and shows significantly less wear than simple mixers, such as ring trough or planetary mixers.

Today, mixers and plants for unshaped products, such as castables, are a growing market for Eirich. A good 40 years ago, these castables consisted of few raw materials, e.g. three aggregates plus 15-20% alumina cement (which limited the application). Horizontal mixers/ploughshare mixers were often used at that time. Then low-cement or even cement-free castables were developed, with up to 20 raw materials, with additives in quantities up to the range of 50 ppm. It became apparent quite early on that horizontal mixers were overtaxed here. Many manufacturers chose a high-quality mixing technology for new plants or replaced mixers in production. The admixing of steel or plastic fibers is also problem-free in the Eirich mixer.