Silobau Thorwesten builds large-dimensioned steel silo for a new cement terminal in Finland for plant manufacturer Ibau Hamburg

In the harbor of Hanko, the southernmost point in Finland, there is presently a cement import terminal being built which will serve as a distributor for the concrete factories in that area. The very well-constructed harbor, about 130 km from the capital of Helsinki, has an appropriate depth of water, comparatively moderate winter conditions, and a geographic location which is predestined for supplying the concrete factories in the south of Finland overland.

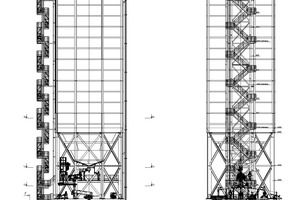

Under this huge project Silobau Thorwesten has received an order from Ibau Hamburg for the delivery of a cement silo, the assembly of which started in early October 2016. This new plant component is a bolted steel silo with 5000 m³ volumetric capacity, which can be disassembled non-destructively in case of relocation. The assembly at site can be executed with a minimum of personnel and will be finished within three months from the start. In addition, Ibau Hamburg is responsible for the delivery of the conveying and loading systems for truck loading, and for the delivery of the marine technology for transport by sea with self-discharging ships. After completion the silo can be charged directly from the bulk carrier using pneumatic conveying. Under-neath the silo the silo trucks will be positioned on a weighbridge and can be charged from 6 loading bellows at once without maneuvering and in the shortest possible time.

During the design phase, the dimensioning has been a particular challenge for the engineers, because silos for such material quantities with their corresponding weight have so far rather been built from concrete than from steel. However, the operator of the terminal regarded the possibility of trouble-free disassembling and relocation of the silo, and at the same time the saving of the enormous costs for demolition and disposal of the concrete type as the decisive factors in favor of this construction. With 14 m diameter and 52 m height the silo reflects state-of-the-art technology in regard to design, construction, and choice of materials.

With this order Silobau Thorwesten GmbH from Beckum, Germany, impressively confirms its market position as an internationally successful provider of innovative steel silo systems that pioneers in many fields of the bulk processing industries, and sets new standards.

//www.thorwesten.com" target="_blank" >www.thorwesten.com:www.thorwesten.com