Simulation of limestone calcination in normal shaft kilns – Part 3: Influence of particle size distribution and type of limestone

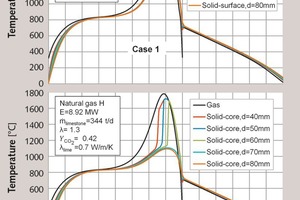

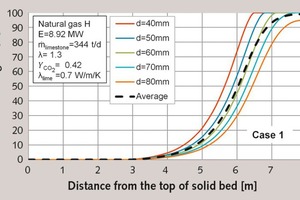

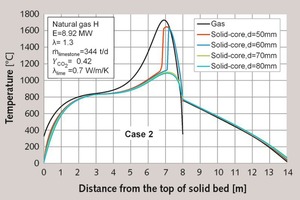

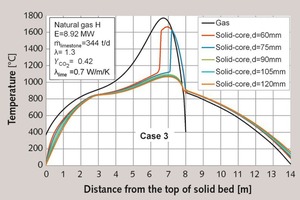

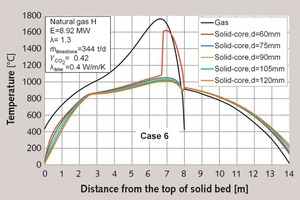

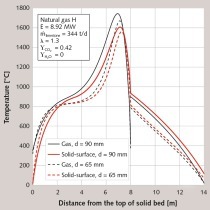

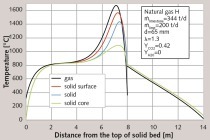

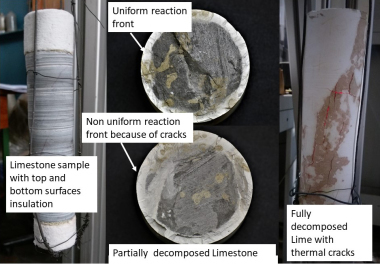

The decomposition process of individual particles with different particle size distributions and different types of limestone will be presented. Residual CO2 can only be found in the largest particles of the distribution. Small particles reach substantially higher core temperatures than large particles. Because of very high heat exchange through radiation, the surface temperatures of all particles are similar. Particles with lower thermal conductivity of the lime shell have lower temperatures and a higher amount of residual CO2 at the same process conditions.

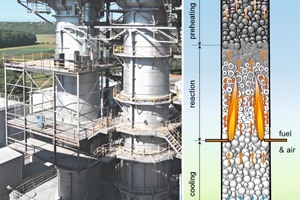

1 Introduction

In the first part of this series, a mathematical model describing the simulation of burning limestone was presented [1]. In the second part examples were presented showing how the process parameters specific energy consumption, mean particle size and bed height effect the limestone decomposition [2]. The effect of the material properties particle size distribution and the type of limestone will be shown in this part. Two typical size distributions, 40 to 80 mm and 60 to120 mm, will be considered. Out of all the material properties, the thermal conductivity of the quicklime has...