The industrial practice of fuel and power saving at JSC Iskitimtsement

The cement industry is the most energy-intensive industry in the construction material sector. So it is no wonder that there are a lot of efforts to reduce the power consumption, especially in Russia, where are still a great many plants working according to the old fashioned and ineffective wet technology.

1 Introduction

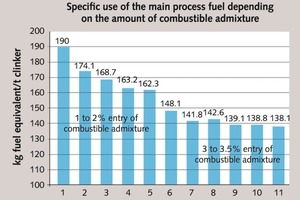

The construction material industry ranks third in heat and power consumption after thermal engineering and metallurgy. The most energy-intensive industry in the construction material sector is the cement industry. In view of the fact that due to the prevailing use of the wet production technology in Russia, more than 200 kg of fuel equivalent, 120 kWh of electricity, and 5 t of construction materials are consumed to produce one ton of cement, the efforts to bring the power consumption down are quite relevant.

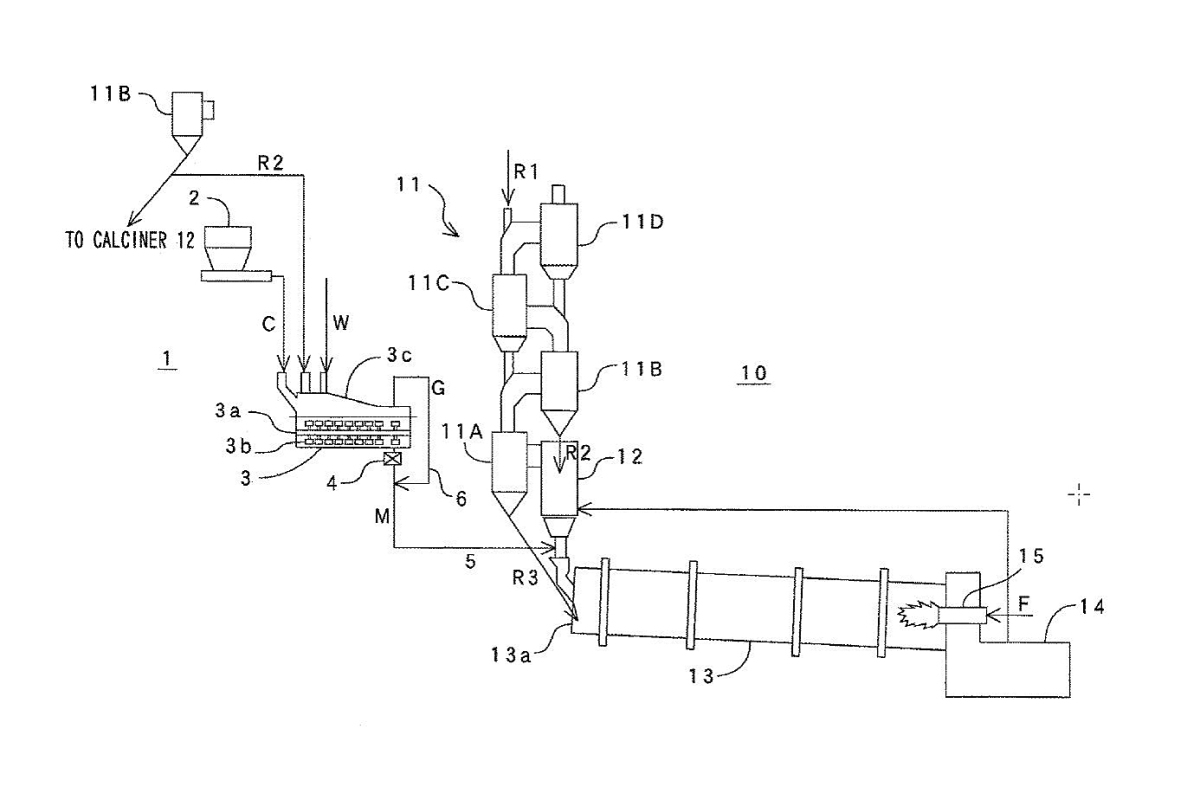

First, it appears appropriate to compare the most important technical...