Radial run-out prediction of girth gears with dual-mesh pinions by means of finite element analysis

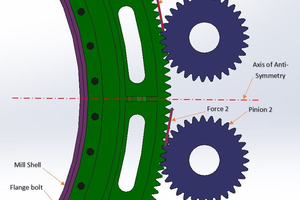

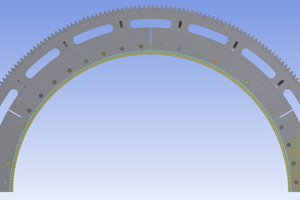

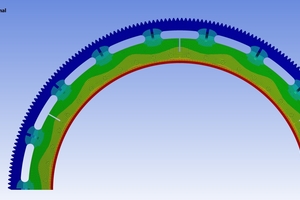

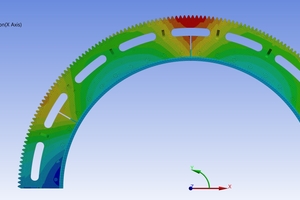

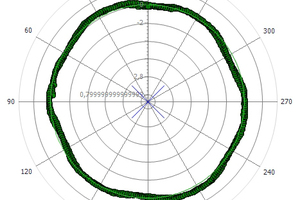

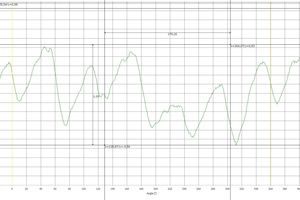

For the successful operation of industrial ball mills, the radial run-out of the girth gear arising out of thermal and structural loads has to be monitored. During operation, the field measurement of radial run-out is a tedious and time-consuming process. In this paper, a finite element-based methodology is investigated for numerically measuring the radial run-out of girth gears. A coupled thermo-mechanical finite element analysis was carried out in an industrial ball mill to establish the temperature profile and, consequently, the radial run-out. Validation of finite element results such as radial run-out was carried out with actual field measurements. The proposed finite element-based methodology accurately predicts the radial run-out at the girth gear of an industrial ball mill.

1 Introduction

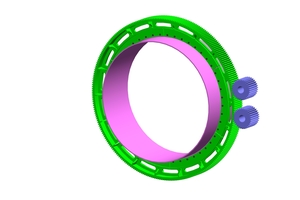

Ball mills are mainly used within the cement and the mining industry for dry or wet grinding a wide range of different materials. Despite the many different applications, the basic design of all ball mills is still a horizontally positioned drum supported by two bearings and rotated by a mill drive. The main dimensions, i.e. diameter and length, as well as the design of the mill are adapted to the actual grinding job. Some mills have very large diameters for autogenous grinding. Other mills are built long and slender for very fine dry or wet grinding in open circuit.

The mill...