Types and characteristics of NOx in cement plant

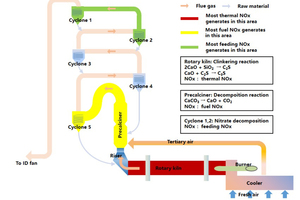

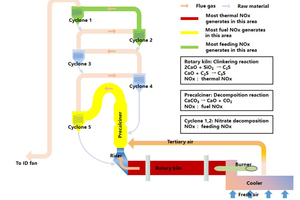

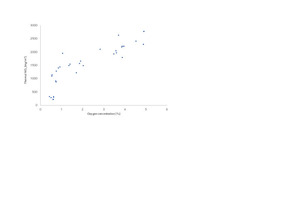

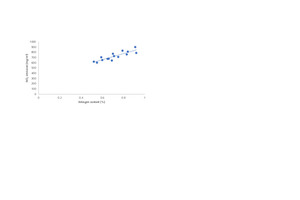

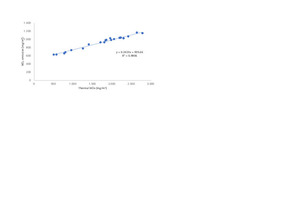

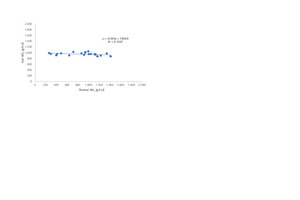

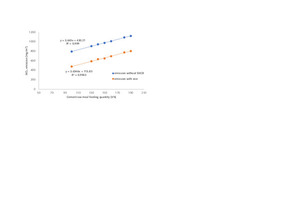

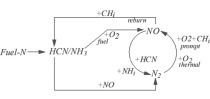

NOx emissions from the cement industry are mainly thermal NOx and fuel NOx. Thermal NOx mainly generates directly from oxygen and nitrogen in the rotary kiln. Fuel NOx are mainly converted from nitrogen-containing compounds in the calciner. At present, Chinese cement enterprises produce not only thermal NOx and fuel NOx, but also the new NOx source – raw material NOx (feeding NOx). In this paper, the characteristics of thermal NOx, fuel NOx and feeding NOx are introduced.

NOx (nitrogen oxides) are one of the gas pollutants from the cement industry. With the improvement of environmental protection standards, many scholars are studying the generation of NOx [1] and the technology for reducing emissions of NOx from the cement industry [2-7]. The authors introduce the characteristics of different NOx from the cement industry, and the NOx emission of the Chinese cement industry.

1 NOx emission in the Chinese cement industry

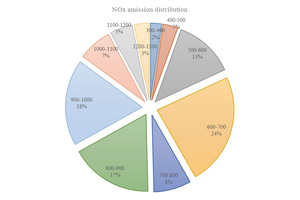

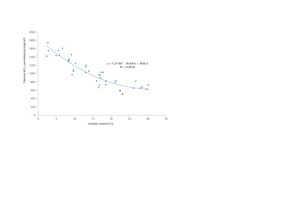

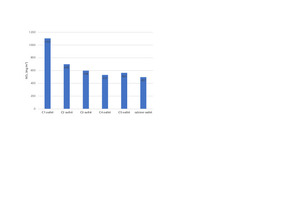

According to the investigation of more than 100 Chinese cement clinker plants without any denitration pretreatment, the NOx emission concentration of cement plants ranges from 400-1200 mg/m3 (note: all NOx concentrations in this paper are Chinese national standard emission concentration, not ppm), and the average value is nearly 800 mg/m3.

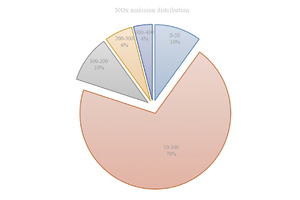

In 2011, the total NOx emission of the cement industry in China was 2.3 million t. In the same year, China began to control the NOx emission from the cement industry. In the emission standard of air pollutants...