Re-Gen visit to ‘green’ cement plant

04.08.2022Representatives of Re-Gen Waste have visited Holcim in Spain to see the process behind the ECOPlanet range of green cement.

Adrian Irvine (WTE Business Development Manager), Joseph Doherty (Managing Director), Aidan Doherty (SRF Project Director) and Colin Doherty (Operations Director) during their Holcim visit (f.l.t.r.) (Photo Re-Gen Waste)

Adrian Irvine (WTE Business Development Manager), Joseph Doherty (Managing Director), Aidan Doherty (SRF Project Director) and Colin Doherty (Operations Director) during their Holcim visit (f.l.t.r.) (Photo Re-Gen Waste)

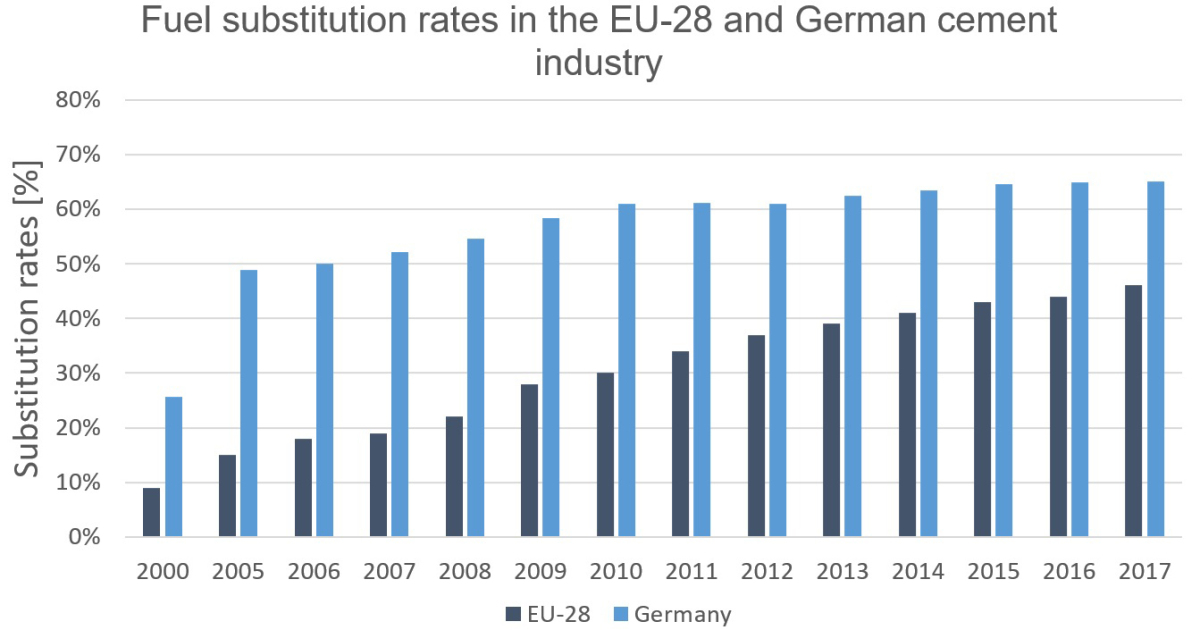

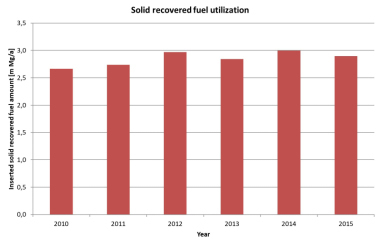

Holcim uses Re-Gen solid recovered fuel (SRF) as a partial substitute for the burning of fossil coal in the heat generation required in cement production.

Joseph Doherty, Re-Gen’s Managing Director, said: “The partial replacement of fossil fuel by SRF is becoming increasingly significant as the cement industry strives toward decarbonisation. Low carbon construction is the future.

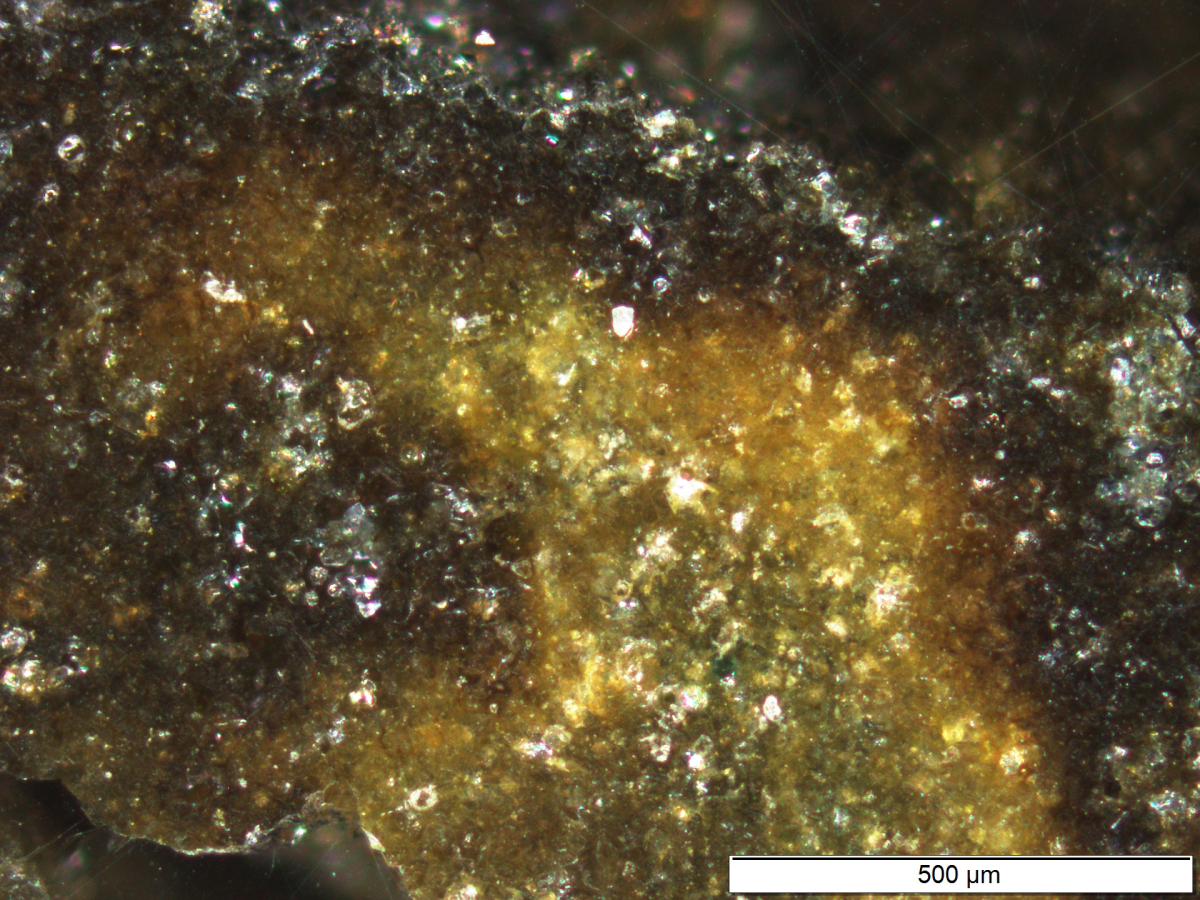

“There are two benefits of solid recovered fuel in cement production. The energy value within the fuel is fully utilised and the high temperature within the process completely destroys all elements of the SRF with remaining ash being incorporated within the cement. The full recovery of energy and complete destruction of the waste derived fuel is another step in Re-Gen’s development strategy.

“Partnering with a multi-national like Holcim allows Re-Gen to be at the forefront of latest technological advances in waste treatment and consistently horizon scan for the next refinement to our processes.”