Betolar starts commercial side stream study of fly ash from Eesti Energia’s power plant

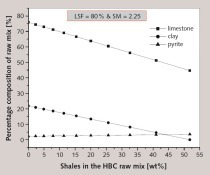

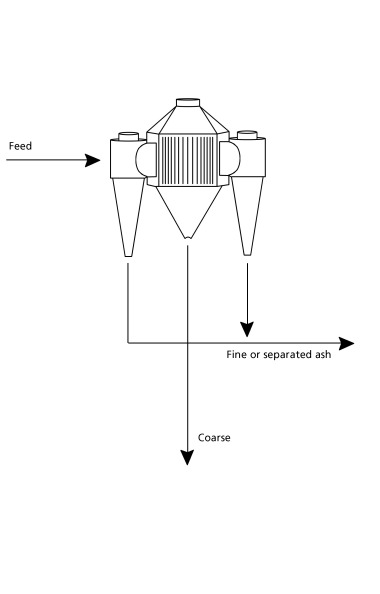

Betolar will start a side stream study commissioned by Eesti Energia to explore the use of ash from oil shale combustion as a binding agent in concrete. This would make it possible to replace cement in concrete either partially or completely. Cement is globally one of the most significant sources of CO2 emissions.

“Oil shale ash is already being used as a substitute for cement in soil stabilisation. Our research aims to find commercial applications with higher added value. Our solutions improve the sustainability and profitability of the value chain of both the mining industry generating side streams and the construction industry utilizing them,” says Ville Voipio, Chief Commercial Officer at Betolar.

Eesti Energia is the leading provider of energy services in the Baltics and the region’s largest wind energy producer. The company’s production of liquid fuels from oil shale will be gradually replaced by the production of chemicals based on a circular economy. One of the current challenges is to identify a solution for the oil shale ash produced by different production processes. Every year, a million tonnes of ash is produced as a side stream of energy production, which has been piled up into mountains of ashes in Narva in northeastern Estonia.

“Our chemical industry based on a circular economy will be almost completely waste-free, as the by-product of each stage will be a raw material for the next product. We see a lot of value for the construction industry in our ashes. The goal of the collaboration between Eesti Energia and Betolar is to identify further applications for the concrete industry. The new ways of use support the sustainable development goals of our operations,” says Veljo Aleksandrov, Project Director at Eesti Energia.

The assignment supports Betolar’s strategy, updated last spring, which focuses on identifying and developing alternative side streams to meet the needs of finding new solutions in the construction and mining industries. Earlier in the autumn, Betolar announced that it was commissioned to carry out a research project to commercialise mining side streams in Thailand. In cooperation with Metso, Betolar’s side stream expertise can be offered to customers using Metso’s lithium processes.

“The new assignments highlight the urgent need for new, circular and low-carbon solutions in the construction and mining industries. We now see the pressure on a sustainable mining and construction industry increasing demand for our patented and commercialized solutions. Side streams that currently end up as waste can be converted to commercially valuable raw materials, and hence reduce the waste load of the mining industry,” Voipio says.