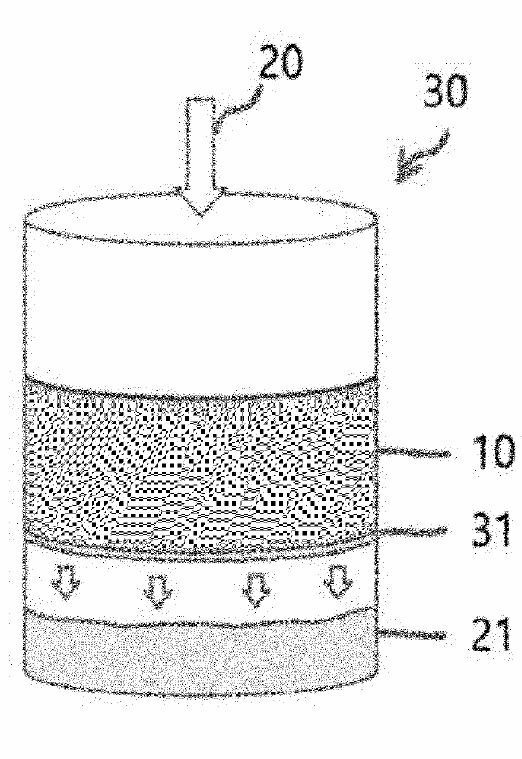

Eco-friendly recycling system and eco-friendly recycling method of cement chlorine bypass dust

(22) 18.08.2022

(43) 27.04.2023

(57) The present invention is an eco-friendly recycling system for cement chlorine bypass dust that prevents scale in pipes when recycling chlorine bypass dust, which is a by-product of the cement process, and dissolves or dehydrates in one or more partial repetition processes and continuous circulation processes, and an eco-friendly recycling method.

(71) Jeong Jae Muk (KR)