A green building in a grey cement plant – transforming bypass dust into industrial salt with the ReduDust Process

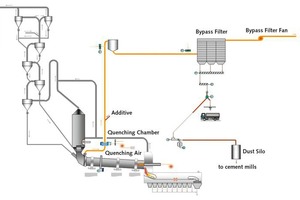

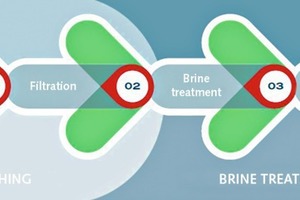

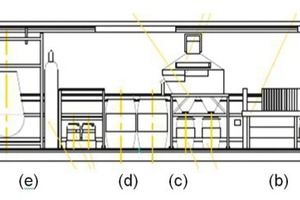

In the Rohožník plant a “bypass dust washing installation” has been installed to enable full incorporation of the bypass in cements and production of chloride salts that can be commercialized. This ReduDust process transforms the problem of a “bypass dust excess” into an opportunity for supplementary sales.

1 Introduction

To reduce its consumption of traditional fuels, like coal, oil or gas, the cement industry is increasingly using solid recovered fuel (SRF). SRF, produced in specialized installations from ordinary industrial or household waste, increases the chlorine input into cement plants. Cement plants typically react to this with a series of measures: extraction of kiln dust, fighting preheater build-ups, and finally installation of a chlorine bypass. Parallel to this, bypass dust can be expediently used in cements and other hydraulic binders. EN 197 sets an ultimate limit of 0.1 % Cl for...