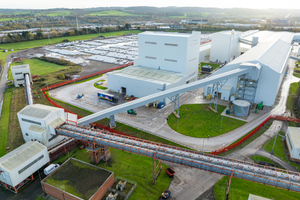

Etex: Inauguration of Europe’s largest plasterboard plant

The opening ceremony of Etex' new plasterboard plant in Bristol also focused on the general market situation for plasterboard, technical innovation and the path to CO2 neutrality in the industry.

New plasterboard plant comes at time of slow market recovery

Etex, a global lightweight construction materials manufacturer, has spent € 200 million on a new plasterboard plant in Bristol – Etex’s largest production investment to date. According to the company, the Bristol extension, which produces plasterboard for the Siniat brand, is Etex’s most efficient plasterboard production line in Europe in terms of line size, speed and complexity. Over 98% of its own plasterboard requirements for the UK and Ireland can be produced here. The factory employs more than 250 people, of which 50 staff are on the new line.

However, like many other industries, the plasterboard market is currently going through turbulent times. In an interview with ZKG Cement Lime Gypsum, Jochen Friedrichs, Head of the Building Performance Division, notes: “Globally, in almost all markets in which we are active, demand has fallen in recent years and is now slowly bottoming out. Of course, this is a mix of different effects. In Latin America, things are slowly picking up again. The trend in Australia is also positive. And in Europe we are seeing slightly better developments in the south, and the market situation in the UK is also showing signs of recovery.”

However, slightly negative growth is still being recorded in two major markets in particular: Germany and France. Friedrichs is nevertheless optimistic: “The negative trend is weakening. We expect a slight recovery next year and an even better development after that.” So does the new plasterboard plant come at a good time to go with the upward trend? “The new plant will enable us to grow excellently with the market and we will always adjust our capacities accordingly.”

Recycling: crucial for the UK’s gypsum reserves

The new Bristol plant leverages new technologies to bring efficiency but also sustainability to the forefront of operations. According to Etex, increasing local production gives greater flexibility and allows for significant carbon savings by decreasing the need to transport boards from other countries. The recycling of plasterboard also plays a significant role here. “For us at Etex, two topics are very important,” states Friedrich. “One is sustainability and the other is innovation. The two areas are naturally linked. Recycling is one of the big areas of work that we have, where we set up strategies and programs to increase the proportion of recycled gypsum. We are the European leader in terms of the proportion of recycled gypsum in total gypsum consumption.”

The head of the Building Performance Division cites two examples: “We have a 40% recycled content at Ferrybridge, our other UK plant - this applies to every board that is produced there. The other highlight we can now present: We have patented a product that has 100% recycled content, 99% including, for example, the paper.” According to Jochen Friedrichs, two factors are crucial to the further development of these technologies: “Firstly, we naturally need recycled gypsum, so we have to build up the supply chain. Secondly, we will have to further learn how to use the technology in the plants so that we can continue meeting our very high quality requirements with regard to recycled gypsum in a stable manner.” Once new knowledge has been gained in one plant, it could in theory be transferred to all other plants. Friedrichs sees the bigger task elsewhere: “The bigger challenge is sourcing, i.e. having these quantities of recycled material in the supply chain on a permanent basis.”

According to Friedrichs, the use of recycling makes sense for plaster and plasterboard in any case, as it is sustainable and conserves resources. Especially with regard to the UK, the use of recycled gypsum is fundamental. “We have 45% of our gypsum requirements locally. Without recycling, we wouldn‘t be able to do what we are doing because we don‘t have any gypsum deposits in the UK and would otherwise have to import it. You would always use recycled gypsum for all products.”

Innovation and sustainability: core element of Etex’ strategy

The new site is a zero waste to landfill plant - and part of Etex’s Road to Sustainability 2030 ambitions - which, in the UK, includes rainwater harvesting and increasing its product recycled content year-on-year. According to Jochen Friedrichs, the company has been well on the way to achieving this goal again since last year: “Our goal is of course to achieve our CO2 targets and we were on track last year, where we achieved our sustainability targets again. And in 2025, I think we will succeed again.”

In general, all current technical developments at Etex are aimed at achieving CO2 neutrality and greater sustainability. Friedrichs presents some current developments here. One approach is aimed at reducing the weight of plasterboards: “Innovations are either lightweight, i.e. reducing the weight of the boards, which saves costs, but is also easier, at least for the installers, because the boards are lighter. The trucks become lighter, the storage areas become lighter, the entire value chain is therefore supported when the boards become lighter.”

Then there is the issue of recycling, i.e. increasing the proportion of recycled materials and, of course, reducing CO2 in production and reducing CO2 in the final building, which all comes together through sustainable systems. “We don‘t just sell Plasterboard as a single product, but complex Plasterboard solutions in essence. And part of our innovation is to always make these Plasterboard solutions measurable as a whole and certified as more sustainable, even to the point of offering to make entire houses carbon-neutral with our solutions.” Friedrichs cites the example of Australia: “There is a business model where the customer can decide to get the entire package carbon-neutral and then the footprint of the building is of course greatly reduced. This also has economic benefits for the customer, but also for the planet. For us, this is a commitment that we take very seriously.” In conclusion, the Head of the Building Performance Division emphasizes: “A core element of our strategy is innovation and sustainability.”