Optimizing rotary kiln design for calcined clay production

This article presents an optimal rotary kiln for calcined clay that decouples drying and calcination. This two-stage approach reduces heat consumption, lowers footprint, minimizes off-gas treatment and enhances operational control compared to traditional single kilns, making rotary kilns an even more competitive alternative to flash calciners.

1 Introduction

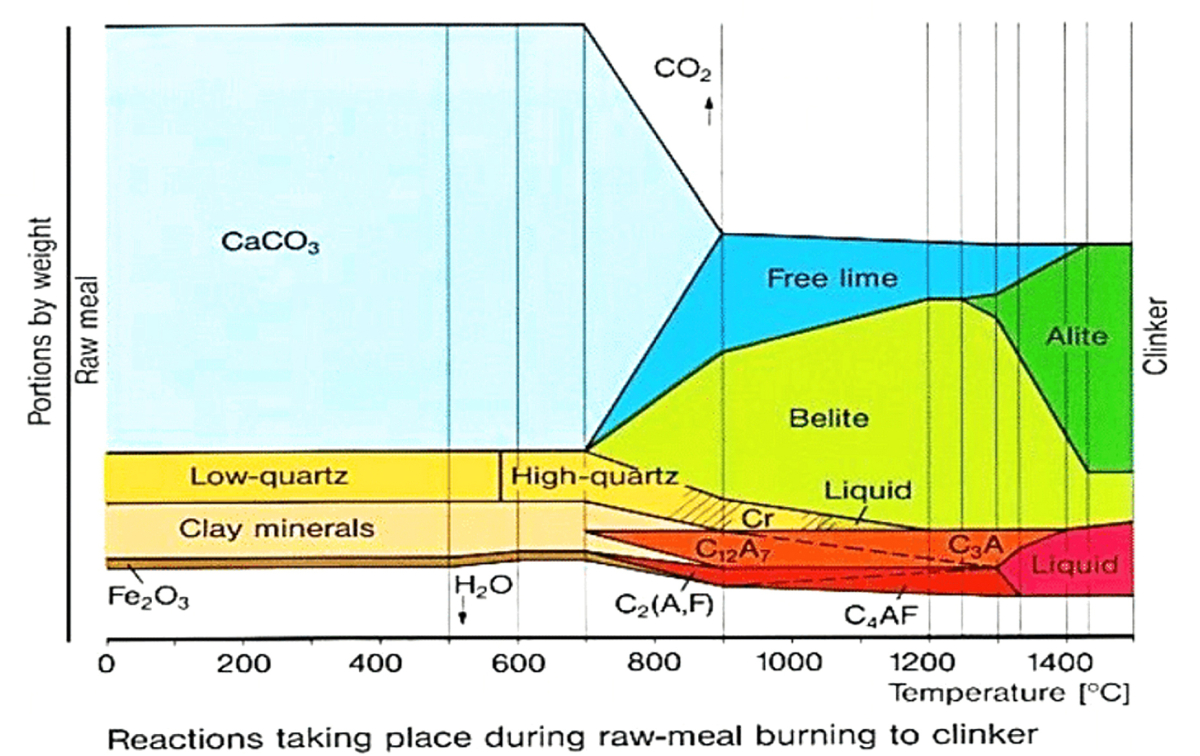

The cement industry is one of the most carbon-intensive sectors, responsible for 5% to 8% of annual global CO2 emissions [1], and its decarbonization is crucial for meeting climate goals. In the United States, the fourth-largest cement producer in the world, the industry emitted approximately 80 million t of CO₂ in 2021 [2]. A significant portion of these emissions originate from the chemical process of calcining limestone to produce clinker, the primary component of ordinary Portland cement (OPC). To mitigate this environmental impact, the industry has intensified its focus on supplementary cementitious materials (SCMs), with calcined clays emerging as a viable and widely available alternative.

Limestone Calcined Clay Cement (LC3), a blended cement that can reduce the clinker content by up to 50%, represents one of the most promising near-term solutions, capable of cutting CO₂ emissions by up to 40% compared to OPC [2]. The production of high-quality calcined clay, the key component in LC3, relies on precise thermal processing. This is primarily accomplished through two leading technologies: flash calciners and rotary kilns.

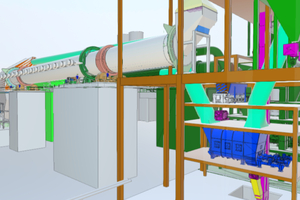

While both have their merits, the traditional rotary kiln design, which combines drying and calcination in a single equipment, presents significant operational and efficiency challenges, related to a combined process control for drying and calcination, a large footprint, its thermal losses and the off-gas volume to be treated. This article introduces an optimized rotary kiln concept, the FCT RotaCalx™ K+D, which separates the drying and calcination stages to overcome the limitations of conventional designs, offering a more efficient, compact, and controllable solution, as illustrated in the project design shown in Figure 1.

2 A Comparison of calcination technologies

Choosing the right technology for clay calcination involves a trade-off between capital expenditure (CAPEX), operational expenditure (OPEX), and product quality control. The financial attractiveness of producing calcined clay is highly dependent on this choice, as well as on factors like the proximity of the clay source [3].

2.1 Flash calciners

Flash calciner systems have been widely adopted in recent years. They are characterized by high thermal efficiency, which translates to lower fuel consumption and consequently lower OPEX, when directly compared to rotary kiln operation. Studies show that a flash calciner can have a specific thermal energy consumption of around 2.0 MJ/kg, compared to 2.8 MJ/kg or higher for a rotary kiln [4]. However, this efficiency comes at the cost of a higher initial CAPEX. They can also present challenges in controlling the final product color, which can be a critical quality parameter depending on the application.

2.2 Traditional rotary kilns

Conversely, rotary kilns generally offer a lower CAPEX solution, making them particularly attractive for smaller-scale production or projects with constrained initial investment. Financial models indicate the investment for a rotary kiln can be around 35-40% lower than for a flash calciner of similar capacity [3]. Their primary drawback lies in higher operational costs, driven by lower thermal efficiency and other systemic inefficiencies inherent in the traditional design.

However, they provide simpler and more intuitive color control, which can be done by traditional methods, like water quenching or co-feeding fuels, or using Inorganic Modifiers (IM). The last one involves adding a calcium source to the feed, which reacts with the iron oxides during calcination to form non-red calcium ferrites, neutralizing the color. This method is not only effective but represents the option with the lowest increase in both heat consumption and CO₂ emissions compared to other techniques [4].

Overall, the optimal calcination strategy for a specific site is determined by a comprehensive analysis of several factors: available capital (CAPEX), existing plant infrastructure, raw material and fuel characteristics, and footprint constraints.

3 Inefficiencies of the traditional rotary kiln process

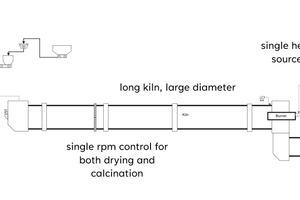

The conventional approach to calcined clay production in a rotary kiln involves feeding moist clay directly into a long, single-shell kiln where both drying and calcination occur sequentially (Figure 2). This integrated process, while simple in concept, suffers from several inefficiencies:

Combined process control: With a single heat source (the main burner) and a single rotational speed for the entire vessel, it is impossible to optimize both the drying and calcination phases independently. This often leads to either suboptimal drying or inefficient calcination

High thermal losses: The long kiln shell results in significant radiative heat loss to the environment, which can account for a substantial portion of the overall energy input. Furthermore, the process often requires water injection into the cooler for temperature control, wasting thermal energy that could otherwise be recovered. The final product and off-gases also exit at temperatures that represent considerable thermal losses

Sub-optimal cooler aeration: In a simple rotary kiln and cooler set-up, the amount of air available for cooling the product is directly tied to the kiln ventilation requirement. Poor cooler aeration leads to low heat recovery from the calcine, impacting overall heat consumption

Large footprint: The need for a long kiln to accommodate both process stages results in a large physical footprint, which can be a major constraint in both greenfield and brownfield projects

High off-gas volume: All gases from both drying and calcination are combined into a single exhaust stream. This large volume of gas must be fully treated for pollutants (VOCs, SOx, etc.), requiring a large and costly gas treatment system

4 FCT’s RotaCalx K+D: A two-stage solution

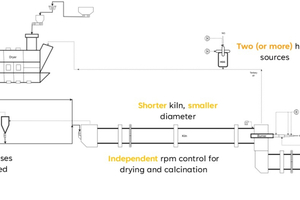

To address these challenges, FCT has developed an innovative kiln system that decouples the drying and calcination processes (Figure 3). This design is based on a shorter, dedicated rotary kiln for calcination, preceded by a separate, highly efficient drying unit.

4.1 System design and principles

The core of the optimized system is the separation of tasks. The raw clay first enters a dedicated dryer, where its moisture is removed under optimal conditions using an independent heat source, such as waste heat from the cooler. The now-dry material is then fed into a significantly shorter rotary kiln, which is designed and operated exclusively for the calcination reaction.

Key features of this design include:

Independent process control: Separate controls for the dryer and the kiln allow for precise optimization of both temperature profiles and residence times

Enhanced heat recovery: The system is designed with an aerated cooler that allows for maximum heat recovery. This recovered hot air can be used as a heat source for the independent dryer, significantly improving the overall thermal efficiency of the plant

Separate exhaust streams: The system generates two off-gas streams. The stream from the dryer, primarily containing water vapor, may require minimal treatment. The smaller, more concentrated stream from the kiln contains the process emissions and can be treated by a smaller, more cost-effective gas treatment plant

The design is flexible and can be integrated with various types of drying technology depending on the specific raw material characteristics and plant layout. Viable options include flash, rapid dryers, single- or triple-shell dryers.

5 Quantifiable performance benefits

The advantages of the two-stage approach are not merely theoretical. A comparative analysis for a 1000 tonne-per-day (tpd) plant highlights significant improvements over a traditional design (Table 1).

The FCT RotaCalx K+D system is more than 50% shorter and has a smaller diameter, drastically reducing the plant footprint. Heat consumption is reduced by approximately 8%, and the volume of gas requiring full treatment is cut by over 40%. This translates directly into lower OPEX and a reduced environmental impact. The enhanced cooler aeration also points to superior heat recovery and efficiency.

6 Ideal for Brownfield and capacity increase projects

The compact nature of the FCT RotaCalx K+D makes it an excellent solution for brownfield projects where space is limited. Existing cement plants can integrate a calcined clay line without requiring the extensive area of a traditional long kiln.

The technology offers a strategic path for capacity increase or product diversification with efficient capital use. Furthermore, this technology can be used to upgrade and increase the capacity of existing rotary kilns, revitalizing this asset. By adding a separate drying unit upstream, the existing kiln can be dedicated entirely to clay calcination, potentially unlocking significant additional production-capacity from the same asset.

7 Conclusion

The production of calcined clay is a cornerstone of the cement industry’s strategy for reducing its CO2 footprint. While traditional rotary kilns offer a low-CAPEX option, their operational inefficiencies have been a persistent challenge. The FCT RotaCalx K+D system, with its decoupled drying and calcination stages, presents a robust and optimized solution. By enhancing thermal efficiency, reducing the plant footprint, simplifying emissions control, and offering superior operational flexibility, this two-stage approach makes the rotary kiln a highly competitive and economically attractive technology for producing high-quality calcined clay.