Significantly reducing compressed air consumption of large filter systems

Cleaning systems of industrial large filter systems are often poorly regulated and therefore consume large amounts of expensive compressed air. That´s over now: A new feature of the solenoid valve controller HE 5750 of Axxeron Hesch electronics allows for an exact setting of the cleaning pressure. Managing Director Werner Brandis explains how exactly pre-pressure control works and what further advantages it offers to the industry.

Great saving potential

Werner Brandis, Managing Director of Axxeron Hesch electronics GmbH, has calculated the saving of compressed air by pre-pressure control. “Let´s take for example a medium-sized filter system with 96 valves, a typical compressed air consumption of 0.05 m3 per valve opening and 2628000 valve openings per year. That will make a compressed air consumption of 131400 m3/a during a 24/7 permanent operation. With a medium compressed air price of 12 cents/m3, that will make € 15768 of annual costs.

Assuming that the medium pressure in the tanks is reduced by 1 bar using pre-pressure control, that will decrease air consumption and thus lower the costs of compressed air by 22%. For our example that means annual savings of € 3500. Since the filter elements must be replaced less frequently thanks to the lower cleaning pressure, there are another € 4800 of savings per replacement period.”

That is because the controllers of the systems are often obsolete. They release the compressed air blast for the filter cleaning in defined time intervals and with constant air pressure - regardless of the actual degree of filter contamination. The intervals of the air blasts are often too short. This consumes more compressed air than is actually necessary.

They have relatively high operating costs because compressed air is quite expensive. But this is not the only disadvantage.

The high number of compressed air blasts reduces the service life of the filter hoses. The cleaning pressure is important, too. You must know that each compressed air blast partially expands the filter fabric. Many compressed air blasts mean that the filter medium must be renewed more often because of the high wear. This also leads to higher costs for the plant operators. And then there is precoating.

A precoating is an auxiliary layer, e.g. of lime or potash, which is applied to the filter fabric to influence the filter effect. Even the finest of gas particles that would normally pass an unprecoated filter, deposit on this layer. If the filter is cleaned too often or too strong, the precoating can detach from the fabric more easily and the filter performance is significantly reduced. Then the precoating has to be renewed, which is expensive.

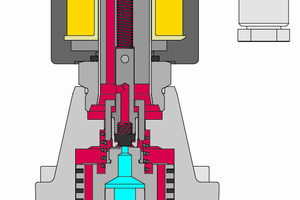

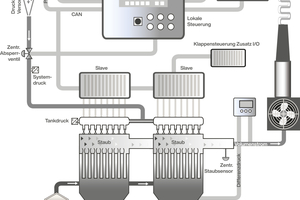

Yes, significantly. With the new pre-pressure control of our master solenoid valve controller HE 5750, the valves only release as much compressed air as is actually required for filter cleaning. The cleaning pressure can either be set differential pressure controlled or volume flow controlled. The requested nominal cleaning pressures for the differential pressure or for the volume flow are determined in a table. Let´s say, for example, at a differential pressure of 50%, I would like to have a cleaning pressure of 3 bar. If the cleaning pressure in the filter system falls below 3 bar after a cleaning process, the HE 5750 opens the central shut-off valve. Compressed air is then refilled into the system, until the desired cleaning pressure is reached again.

If the cleaning pressure exceeds the previously set value, the HE 5750 activates the shut-off valve, which is then closed. Once the shut-off valve is closed, compressed air can no longer flow into the pressure tanks that feed the cleaning valves. The pressure tanks are therefore filled up to the respective calculated cleaning pressure. The pressure is released indirectly via the valves only i.e. during the cleaning process.

Yes, there are indeed. We have calculated that for a medium-sized filter plant with a compressed air consumption of approx. 130000 m³ and compressed air costs of approx. € 16000 per year, € 3500 can be saved annually using the pre-pressure control. Considering that the filters have to be replaced less frequently due to the lower cleaning pressure, that will result in another € 5000 of savings per replacement period (see info box). Well-known customers have been convinced by this efficiency and reliability: Our HE 5750 is used, for example, in one of the world’s largest energy-from-waste plants in Dubai. Also, the Basin Electric Dry Fork power plant in Gillette/Wyoming (USA) has been using our controller for many years. It is the world´s largest plant with a circulating fluidised bed dry desulphurisation.