10 years of EMC bagfilter-technology

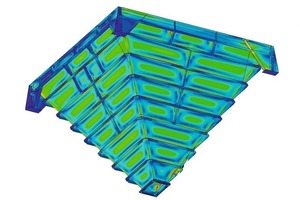

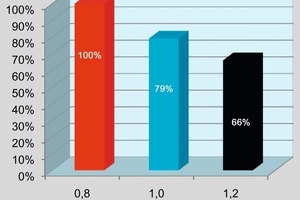

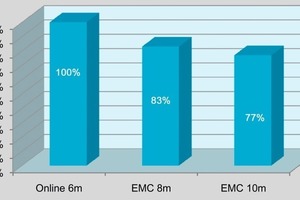

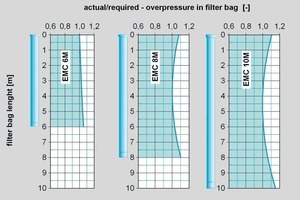

Summary: In the last decade, EMC bagfilter-technology from Scheuch GmbH, Aurolzmünster/Austria, has revolutionized the cement industry and has introduced new standards for filter bag length, pressure drop, cleaning pressure and bag service life. The result has been a significant reduction in life cycle costs (LCC). Thanks to the granted patent, EMC is unique and counts as Best Available Technology (BAT) for process filters – even compared to electrostatic precipitators and reverse air filters. The use of 8m filter bags (EMC 8M) has meanwhile become standard, while 10m filter bags (EMC 10M) have already been installed in systems with capacities above 500 000 m³/h. More than 160 installed EMC systems within the first ten years underline the superiority of this technology worldwide (Fig. 1).

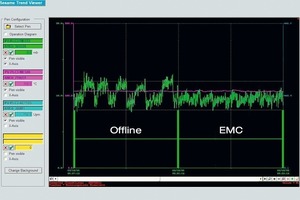

Due to the sum of its advantages compared to other systems, EMC filter technology is regarded as the yardstick. It combines the advantages of online and offline cleaning. Other suppliers attempt to copy EMC with similar solutions, e.g. semi-offline, but do not achieve equivalent results.

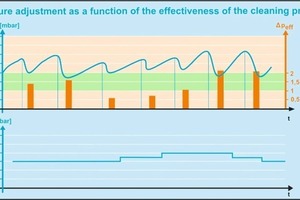

Offline cleaning provides two significant advantages compared to online cleaning: considerably lower differential pressure of the filter and higher filter bag service lives due to the gentle cleaning in the no flow state. However, it does have the disadvantage of severe differential pressure...