The use of alternative fuels in PFR kilns

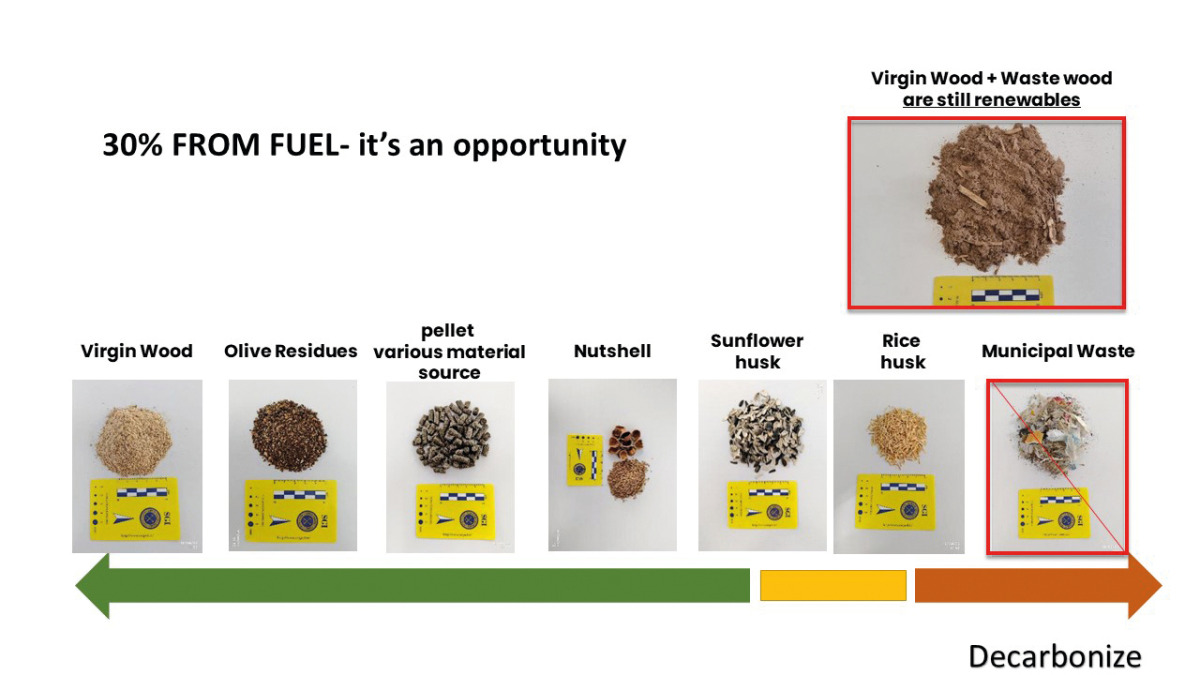

In recent years, the adoption of alternative fuels has become a key factor in the sustainable evolution of the lime industry. In particular, the use of biomass is emerging as an effective solution to reduce environmental impact while ensuring a more flexible and resilient energy supply. These fuels primarily offer the advantage of being environmentally sustainable, significantly contributing to the reduction of the industry‘s carbon footprint. Additionally, they allow producers to diversify energy sources, reducing dependence on traditional fossil fuels while ensuring greater operational flexibility and cost optimization. Biomasses could moreover represent a cost-effective option, especially in regions where it is readily available at competitive prices. Currently, the market offers a wide range of biomass sources, from virgin wood to agricultural waste and residues from the wood processing industry. Each type has specific physicochemical properties that must be carefully analyzed and assessed—not only to optimize combustion and calcination processes but also to ensure efficient handling, feeding, and dosing within lime plants.

Introduction

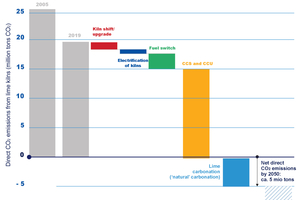

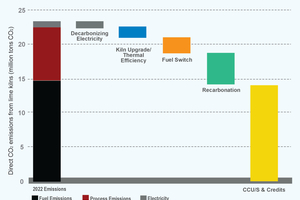

In the context of the growing global commitment to decarbonizing industrial processes, the lime industry is aligning itself with this crucial objective. Following international trends and directives on sustainability and emissions reduction, the sector is adopting a range of strategies aimed at lowering the environmental impact of production.

Many of these strategies have already been outlined and promoted by leading industry associations at both national and international levels, underscoring the urgency and concreteness of the actions required. Among the key milestones on the path toward more sustainable production, the energy transition stands out: shifting from traditional fossil fuels to alternative fuels is a crucial lever for reducing CO₂ emissions and improving the environmental performance of lime plants.

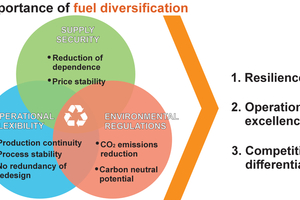

The strategic value of fuel flexibility in lime kiln operation

In the operation of modern lime kilns, fuel flexibility is no longer a luxury, it is a strategic necessity. The ability to utilize multiple types of fuel offers a range of technical, economic, and environmental benefits that can significantly enhance the reliability and efficiency of the lime production process.

One of the most immediate advantages is operational continuity. In the event of supply disruptions – such as interruptions in the availability of natural gas – alternative fuels like coal or biomass can be employed to maintain kiln operation without unplanned downtime. The capacity to switch fuels ensures resilience in the face of volatile energy markets or logistical challenges.

From an economic standpoint, cost optimization is a key driver. Energy costs represent a significant portion of the total operating expenses in lime production. Having access to multiple fuel sources allows operators to respond dynamically to price fluctuations by selecting the most cost-effective option or implementing co-firing strategies. This approach not only reduces fuel costs but can also improve the thermal efficiency of the kiln.

The quality of the final product, particularly high-purity quicklime (CaO), is strongly influenced by combustion conditions. Different fuels generate varying flame temperatures, heat distribution profiles, and combustion atmospheres, all of which can affect the decarbonation process and the reactivity of the lime. A diversified fuel setup enables more precise control of process parameters, supporting consistent product quality.

Environmental performance is another major consideration. With growing regulatory pressure to reduce carbon emissions, the use of alternative or renewable fuels—such as waste-derived fuels or biomass – offers a pathway to partial or full decarbonization of the lime production process. This not only lowers the carbon footprint but may also facilitate compliance with emission regulations and access to environmental incentives.

Finally, fuel flexibility supports long-term strategic planning. It provides operators with the agility to adapt to changing fuel availability, future carbon taxation, or shifts in energy policy – ensuring the kiln remains economically and environmentally sustainable.

Cimprogetti has built a strong track record in developing multifuel systems that support the transition to more sustainable industrial practices. Since the 1990s, the company has implemented 51 projects designed to operate with flexible fuel strategies, including interchangeable or blended use of gaseous, liquid, and solid fuels. This adaptability enables clients to reduce reliance on fossil fuels and progressively integrate renewable sources. Notably, a growing number of recent projects feature biomass as a primary or complementary fuel, reflecting Cimprogetti’s commitment to lowering carbon footprints and advancing cleaner energy solutions within lime production and related sectors.

What does it mean, biomass?

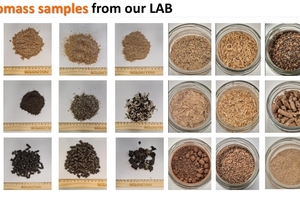

Switching to biomass isn‘t as simple as just changing the fuel. To make it work efficiently and safely in a lime kiln, it‘s essential to understand what kinds of biomass are available, how they behave, and what kind of adjustments the kiln system might need.

Not all biomass is the same. When we talk about biomass, we refer to a wide range of organic materials that can be burned to produce heat. These can come from:

Wood-based sources, like wood chips, sawdust, or pellets

Agricultural waste, such as nuts, shells, husks, or other residues

Organic waste, processed from food waste or by-products of industrial processes

Ground wood waste: recovery of disused wooden artefacts

To successfully integrate these fuels, it is essential to thoroughly characterize their properties. Each of these types of biomass has different properties that can impact how well they burn, how much energy they release, and how they affect the kiln and its emissions. Moreover, the feeding and dosing system must be designed to suit the specific characteristics of those biomasses. That’s why Cimprogetti has implemented its own methodology to design and develop projects aiming to use biomass as single source or one of the options in a multifuel project.

The first step is the fuel characterizations, to obtain accurate data that will be used by Cimprogetti engineers to select the proper fuel system configuration. When characterizing solid fuels for lime kilns, the following aspects are critical:

Proximate analysis:

Moisture content: High moisture reduces calorific value, affects ignition and causes material handling problems

Volatile matter: Influences ignition and flame stability

Fixed carbon: Represents the solid combustible fraction

Ash content: Could impact the final quality of the quicklime or could give indication about the abrasiveness behavior

Elemental analysis:

Knowing the content of specific elements could support the design, predicting the pollutant content of waste gases or residual impurities in the quicklime. This is the case for Nitrogen and Sulphur content.

Calorific value:

This value determines the amount of energy released during combustion, typically measured as higher heating value (HHV) or lower heating value (LHV).

Physical properties:

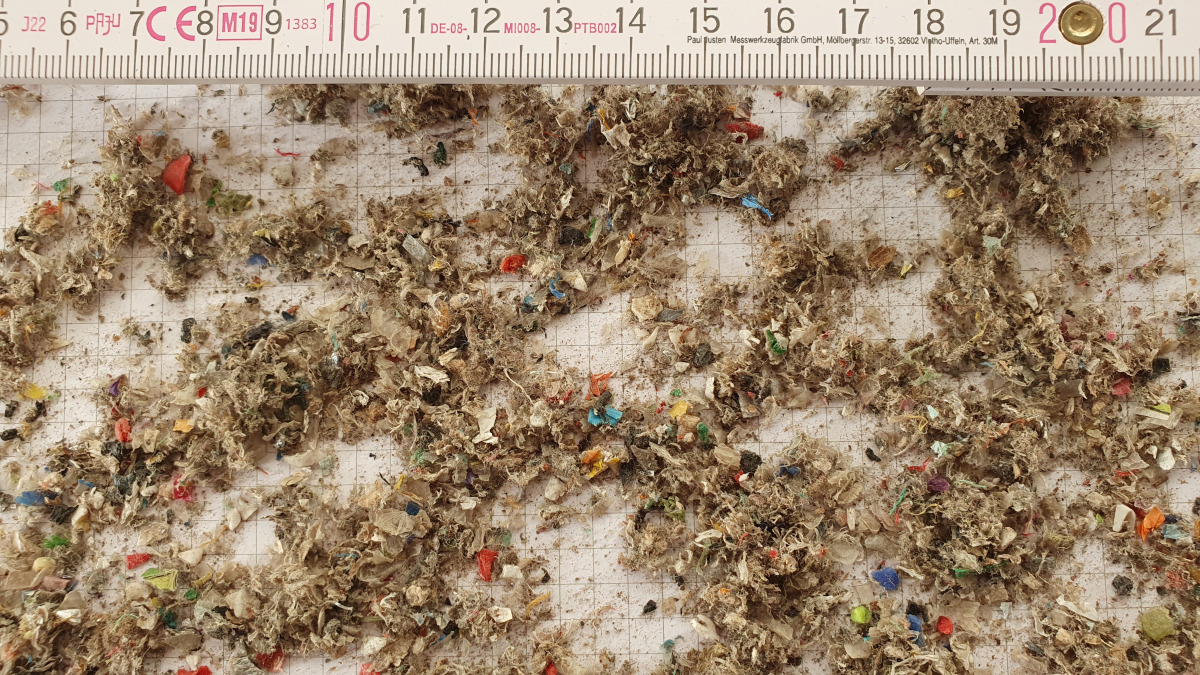

Particle size and shape could affect the handling and feeding system. Particular attention must be paid to the presence of needle shapes and fibers. Those types of particles are very dangerous for the feeding system and if not correctly handled could compromise the entire feeding system. Granulometry has to be properly prepared, since excessively large particle dimensions are not suitable to be conveyed and burnt through the burning lances of a PFR lime kiln.

Bulk density:

This property influences storage and transport. If the use of multiple solid fuels is anticipated, each dosing device must be designed to ensure a proper balance, taking into account the different fuel densities.

Grindability:

This parameter can give feedback on fuel preparation needs. A second step of analysis focuses on the explosivity parameters, to allow the proper design measure to avoid, mitigate or handle the risk of explosion while operating with powdered fuels. Biomass dust, when suspended in air at certain concentrations, can form explosive atmospheres.

Key parameters include:

Maximum explosion pressure (Pmax): The highest pressure generated during an explosion

Maximum rate of pressure rise (dP/dt)max: Reflects the explosiveness or how rapidly the pressure increases

Minimum ignition energy (MIE): The lowest energy capable of igniting the dust-air mixture

Deflagration index (kst) quantifies the explosiveness of a combustible dust. It indicates the relative severity of a dust explosion, should one occur.

Understanding these parameters is critical because biomass fuels can vary widely in their explosivity, sometimes posing higher risks than fossil fuels.

All those above mentioned parameters have an influence in the design of the solid fuel feeding and dosing system.

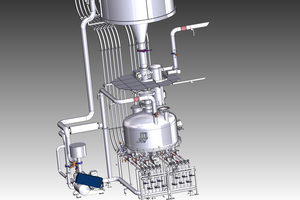

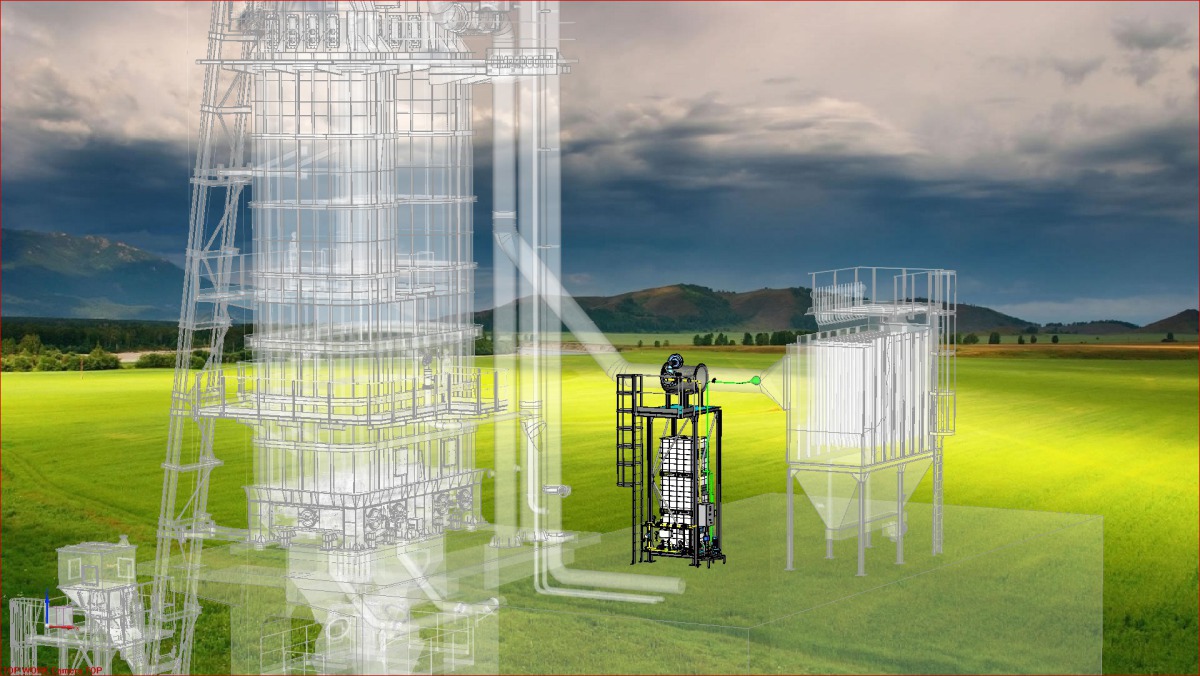

The CIM-FIRESOLID System

CIM-FIRESOLID is Cimprogetti’ s advanced fuel handling system, engineered to accurately feed and dose a variety of solid fuels into lime kilns. It was originally developed for traditional fossil fuels like coal and petcoke and then transformed and integrated with specific features enabling the use of a wide range of biomasses under the same process design concept.

At its core, the systems consist of two main components:

a fuel storage system

a weight-loss dosing system

Below, we explore the key components of the CIM-FIRESOLID system and the main design criteria involved.

Fuel storage silo system

The storage silo acts as a daily reserve tank, holding the pulverized fuel before it is cyclically fed to the weight-loss dosing system. Fuel can be loaded into the silo through various methods, including mechanical feeding systems or pneumatic transport systems for powders.

A level indicator continuously monitors the silo’s fill level and manages refilling requests.

To prevent the risk of explosion, and in accordance with the general principles of explosion risk assessment, storage silos are usually equipped with explosion relief panels that safely vent any possible explosion pressure, meeting worldwide standard requirements. These panels can be designed to release all or part of the pressure generated by an explosion.

The silo is also typically fitted with a fabric filter (bunker filter) connected directly to it, designed to handle airflow from pneumatic transport feeding (if present) and/or any fluidization air introduced at the silo outlet.

For fire prevention, temperature probes and CO detection systems are installed inside the silo. These instruments provide early warnings of ignition risks caused by embers introduced during loading or by self-heating phenomena—especially common when storing biomass fuels.

To tackle potential fires, the silo includes connections for inert gas injection. Depending on the type of fuel and local fire safety regulations, water-based fire suppression systems may also be installed.

At the silo’s discharge outlet, working with biomasses could generate a first challenge, related to the flowability of material. The system is typically designed to feed the dosing tank in a very short time, in order to minimize the non-fuel supply into the kiln, equal to a non-productive timeframe. According to the specific biomass behavior, Cimprogetti has implemented different solutions at the bottom discharge of the silo.

Free Flow: is the simplest system that can be installed at the bottom of the silo. It works well when the biomass has a very fine particle size without needles and fibers. To facilitate the biomass discharge when opened, a fluidification system is always foreseen with a set of peripheral aerators, on multiple levels over the discharge mouth.

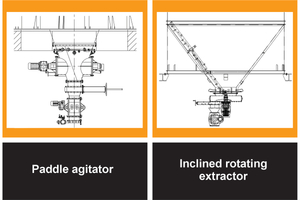

Paddle Agitator: is the solution to be selected when the fuel has a low tendency to form bridges above the discharge mouth. The horizontal shaft, equipped with a series of blades, rotates to break up the compacted material, encouraging the release of biomass which then flows freely out of the silo.

Inclined rotating extractor: a robust rotating scraper that works around the entire cone of the silo, to break the agglomerates, forcing material to come out from the silo. It is a powerful solution when handling sticky fuels or particles mixture with a high tendency of bridge formation.

Multi-Screw Extractor: a large diameter solution when a high flow of material is required and the fuel has a very low density.

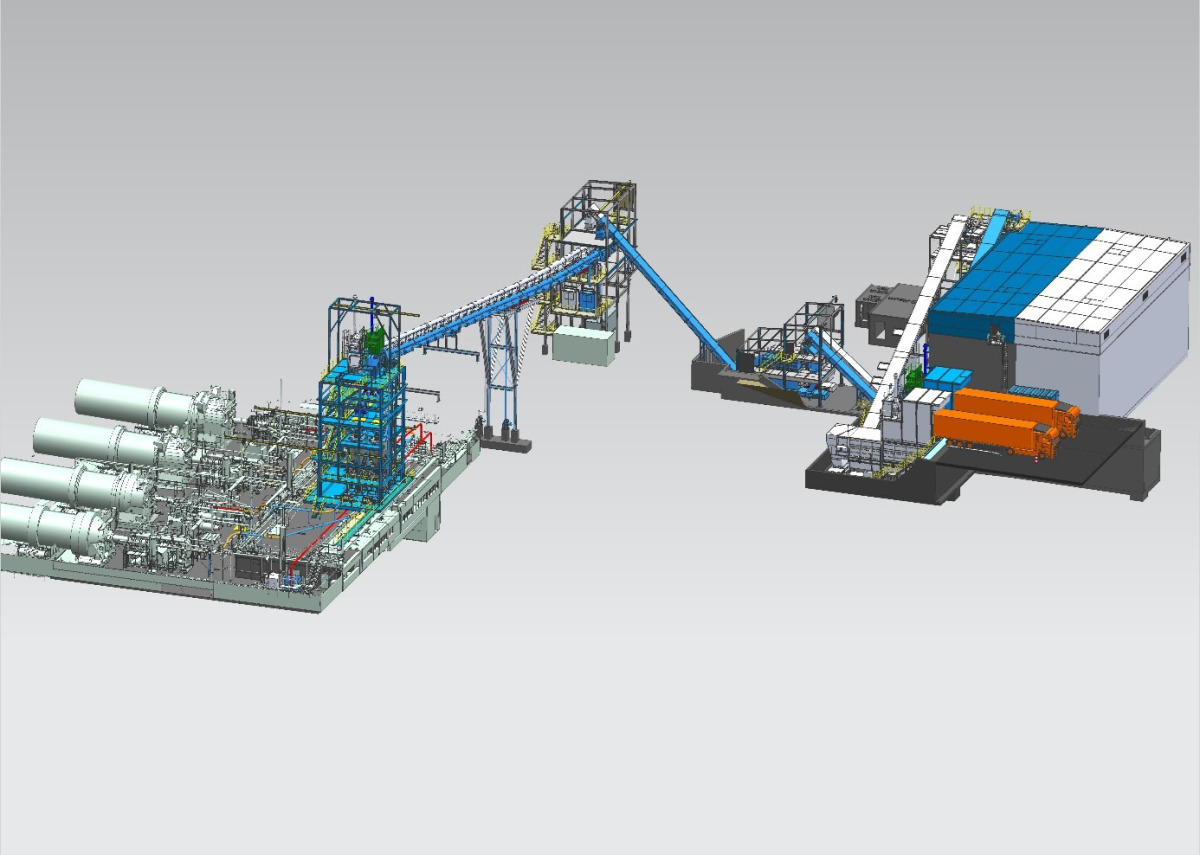

Loss in weight dosing system

This system consists of a tank mounted on load cells that measure the weight of the fuel received from the storage silo.

Fuel discharged from the hopper passes through several outlets at the bottom; each fitted with rotary valves (rotary feeders). The number of these valves varies depending on the production capacity of the lime kiln served by the CIM-FIRESOLID System.

The rotary valves are controlled by a dedicated system that regulates their speed to meter the fuel accurately. Fuel extracted by the valves is then pneumatically conveyed through pressurized pipes towards the kiln. A volumetric compressor supplies the transport air, creating a dilute-phase pneumatic conveying system.

During operation, the load cells continuously measure the hopper’s decreasing weight. Once the required fuel amount is delivered to the kiln, the rotary valves stop, and the hopper prepares to refill from the silo. At this stage, the compressor halts pneumatic transport air, and the sealed hopper must be depressurized.

Pressure relief valves at the hopper’s top open after a pair of fabric filters connected directly to the hopper. These filters trap the fuel dust inside, allowing only clean air to be released into the atmosphere.

To ensure uniform fuel flow within the hopper, a rotating shaft distributor is installed at its bottom.

Additionally, compressed air fluidization systems are installed at the hopper outlets, aiding fuel discharge through the rotary valves.

For fire safety, the hopper is equipped with temperature sensors and optionally CO detectors, mirroring the setup of the silo. These devices detect ignition risks caused by embers or self-heating, especially when biomass fuels are involved. Inert gas injection connections are also provided for emergency fire suppression.

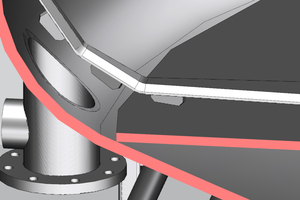

Once again, the biomasses usage forces Cimprogetti to introduce special features on the traditional dosing system. The first was a set of blades at the tip of the agitator to scrape the pulverized material, ensuring a better feeding through the tank outlet mouths.

Another important aspect while using biomasses is related to the rotary valves. Experience has brought Cimprogetti to conduct trials with real biomass samples, to check and ensure the proper design of such equipment. So nowadays, there could be different options for rotary valves design; not only influenced by density and required flowrate, but also by flowability of the material and particle shapes. The rotor can be designed with different configuration such as straight or inclined blades and eventually be equipped with a special blade capable to cut coarser particle under specific condition.

A further challenge emerges due to the high demand of biomasses and the consequent need to find different sources: mixing different pulverized solid fuels.

When burning agricultural biomasses, due to the seasonality of such products, the amount of available material is not always constant, as growth, harvest and industrial processing requires specific periods of the year. In order to compensate for such amounts of fluctuation, it is possible to introduce a second fuel (another agricultural fuel or a traditional one) and blend them together to obtain stable and uniform fuel over the years in enough quantity as per lime kiln requirement. Another reason to mix different solid fuel encountered along Cimprogetti’s experiences has been the aim to start using biomasses, without completely abandoning traditional fossil fuels, like coal or petcoke. The resulting blend of solid fuels can be totally different from both original sources, and it is not only a matter of mathematical proportion between the two involved fuel. The proportional ratio approach is right when considering parameters like calorific value or fuel composition but once looking at density or flowability of the final blend, it is something not always predictable on paper. Cimprogetti has opted for a workshop trial, with a real mixer to study behaviors and measure the specific characteristic of each blend with differing mixing percentages.

As practical illustrations of the preceding discussion, the following multifuel projects demonstrate the integration of biomass within their configurations.

The first project is centered to a plant where an existing lime kiln, working with petcoke, has been upgraded with a new CIM-FIRESOLID System working with multiple fuels: Natural gas, petcoke and a set of agricultural biomasses (olive waste, almond shells and rise husks).

Each fuel can be used as a single source or in blend with others. So, in this plant, it is possible to operate with a blend of natural gas and solid fuel or with a blend of two different solid fuels. This way, the plant can enter a new sustainable era using multi-agricultural alternative fuels, available in different quantities throughout the year. The petcoke, still available at site, can continue to be used during the first transition period, and the natural gas can work as a spare fuel for emergencies, during kiln warm-ups, or as a correctional fuel for process stability or waste gases emission correction whenever required. In this plant, an inclined shaft extractor was selected, working very well with all the solid fuels foreseen and, of course, between the feeding silo and in the dosing tank, it has functioned as a mixer for the fuel blending.

The second case is related to an existing plant where a kiln working with natural gas has been converted into a multi-fuel system, working with waste wood biomass and natural gas. Both fuels can be used as a single source or in a mixture of fuels, under a specific blending range. The peculiarity of this project was the biomass type, since – due to a high content of fibers and needles – there was a strong tendency to create large diameter bridges of material over the discharge mouth. To solve this issue, an inclined shaft extractor with special scrapers has been developed. It is able to break the bridges and allows a uniform flow of biomass through the silo discharge mouth.

The third case is a CIM-FIRESOLID system serving two kilns simultaneously. The system is composed of two silos, one for petcoke and one for biomass. Each fuel can be used alone or in a blend. To blend the solid fuels, once again, a mixer on load cell has been introduced to monitor the quantity of the mixing receipt. On the silo, a multiscrew extraction system minimizes the tank feeding time. The multiscrew extractor has also a further point of flexibility: screws can work together to feed one kiln only or they can work one half for one kiln and the second half for the other kiln. This feature enables the common CIM-FIRESOLID system to serve simultaneously both lime kilns.

Safety requirements in the design of automated solid fuel dosing systems

Finally, to complete an appropriate design for a multi-fuel firing system it is necessary to consider all the safety requirements. The handling and transport of solid fuel materials like biomasses implies significant safety challenges due to the combustible and explosive nature of these materials. The first step is risk assessment. After the fuel characterization, it is important to classify all the zones of the plant, for instance applying ATEX zoning based on the likelihood and duration of explosive atmospheres. Then the system design must incorporate safety at every level, considering the use of adequate certified components, avoid dust dispersion, prevent electrostatic discharges that can act as a source of ignition and use fail safe controller (PLCs).

Designing for both prevention and protection is essential: the use of intrinsic safety instruments, foreseeing venting panels to convey explosion or suppression and isolation systems to prevent flame propagation across sections. Functional safety is also an essential part of the design, following IEC 61508 or ISO 13849 standards to assign SIL (Safety Integrity Level) or PL (Performance Level) to safety-related control systems.

In conclusion, designing an automated solid fuel dosing system requires a multidisciplinary approach that balances efficiency with uncompromising safety. By integrating hazard assessment, explosion prevention, and compliance with international standards, engineers can develop robust systems capable of operating safely in high-risk environments.

Conclusion

Cimprogetti, as a complete full-solution provider for the lime industry, has developed extensive expertise in recent years in the management and integration of biomass into lime production processes. This includes the use of biomass either as a single fuel source or as part of a multifuel system. The latter approach is often driven by the goal of diversifying fuel sources to enhance flexibility and sustainability. Through a detailed analysis of each fuel’s characteristics, lab test and workshop trials, innovative plant solutions have been implemented to ensure flexibility in dosing systems, efficiency in combustion processes, and operational safety.

Real-world cases of biomass implementation in PFR kilns highlight the main challenges encountered and the solutions adopted to ensure a stable and efficient production process. Fuel diversification is not only a challenge but is a real proven opportunity and a consolidated strategy for the lime production of the future.