Introduction

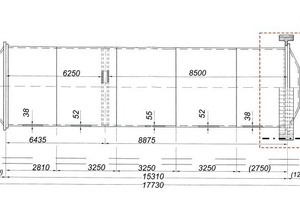

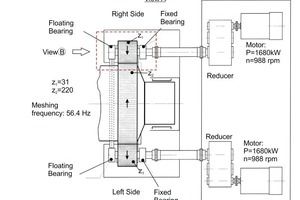

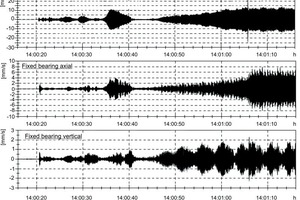

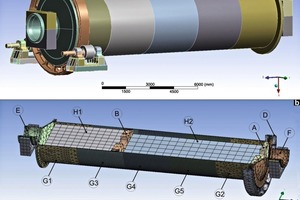

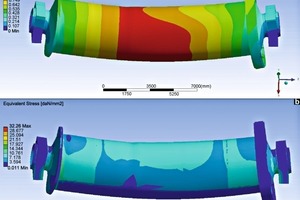

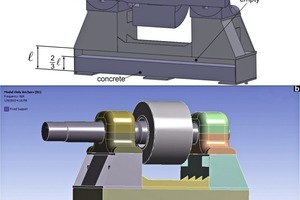

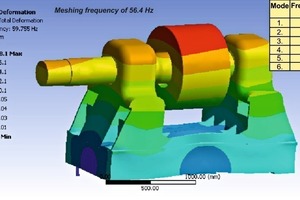

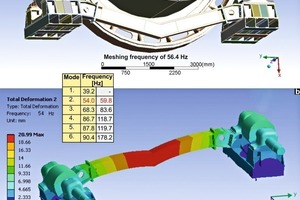

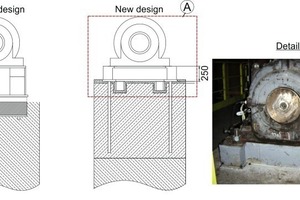

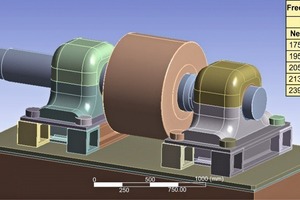

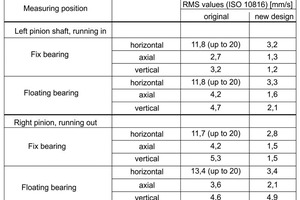

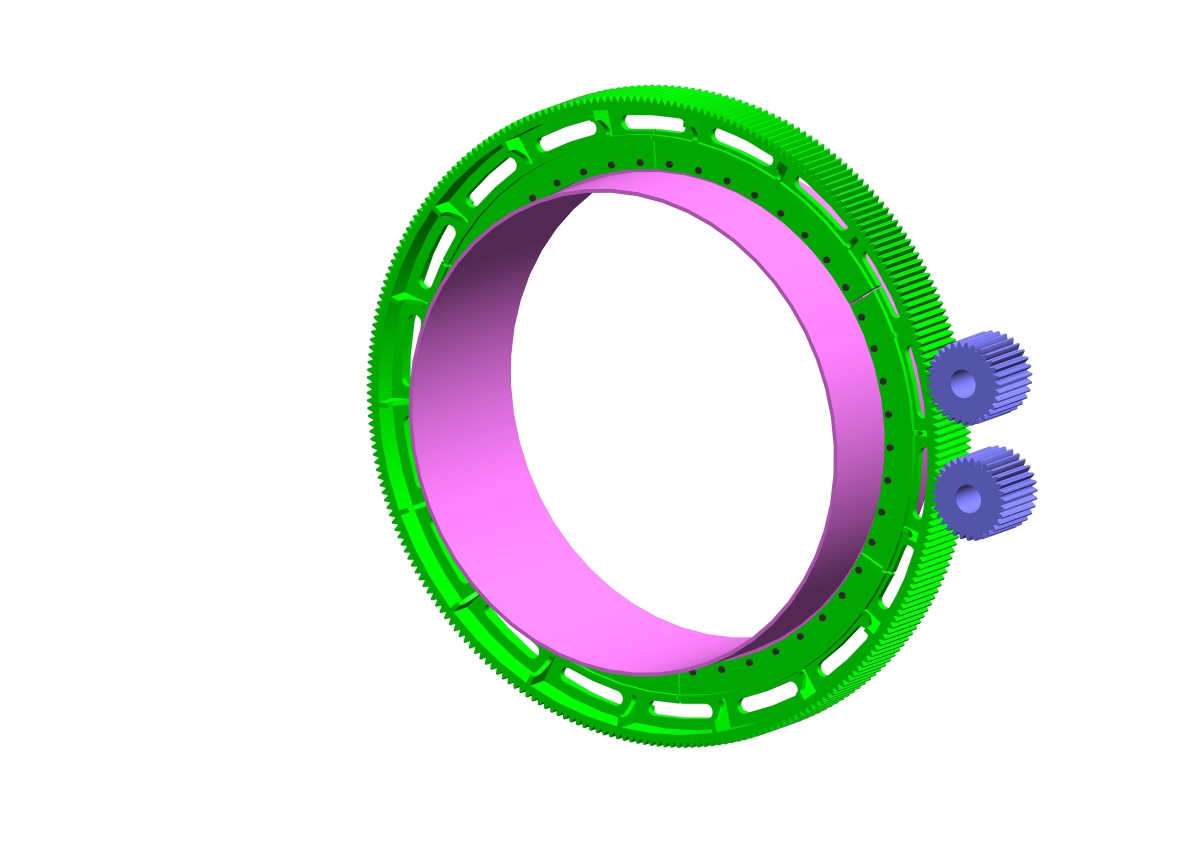

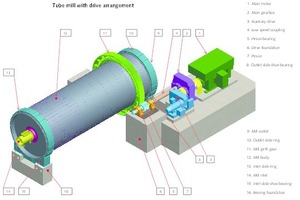

The dynamic behaviour and thus the operational reliability of large mechanical installations such as cement mills can be strongly affected by the basement of their driving units. Increased vibrations, mainly in the region of the two pinion girth gear housing basements of the double mill drive were measured during the operation of a cement mill in the Halkis plant of Heracles General Cement Co (Lafarge Group). These led to excessive damages to the tooth flanks of the pinions. The pinions were replaced without avoiding the intense vibrations in both pinion housings. To detect the...