BCT Technology – a new alternative binder concept

Additives can be used, however, to further improve the CO2 balance of products based on Portland cement. These alternative substances are by-products from steel manufacturing or coal-fired power plants, and serve as source materials for composite cements. Portland cement clinker is partly replaced, for example, by blast furnace slag, fly ash, or silica fume, whereby the specific use of these additives often even improves the properties of the cement product. However, this is only possible to a certain extent because of the limited availability of high-quality raw materials.

The HeidelbergCement Technology Center (HTC) goes one step further: In an effort to tap the further potential for CO2 reduction, for several years HTC has been working on the development of alternative binders that work more or less without conventional clinker. Since the beginning of 2010, new staff has been hired at the HTC Global research centre in Leimen/Germany, to develop concepts for alternative clinker (Fig. 1). A previous internal study from 2009 systematically analysed all of the concepts known at the time.

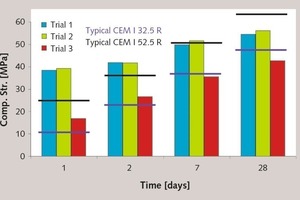

One of the most promising concepts in this study was a calcium sulfoaluminate-belite binder (CSAB). Calcium sulfoaluminate (CSA) cements have been produced for use in building chemicals for a long time, especially in China. They are mainly used in screeds, tile glues, and special products. A characteristic feature is that they form ettringite very quickly and therefore exhibit a very high early strength (Fig. 2). Experiments have already been performed with a view to using these cements for construction purposes, but their durability has not yet been sufficient. Nonetheless, Dr. Wolfgang Dienemann, Director of Global Research & Development HTC, sees a worthwhile approach: “If we combine CSA cements and their high early strength with belite (dicalcium silicate), the slow-reacting clinker phase in classic Portland cements, it might be possible to combine the advantages of both systems in one cement. The ettringite formation is responsible for the early strength, while belite hydration – as with Portland cement – leads to calcium silicate hydrates, which form a permanent and durable structure. This combination seemed promising enough to us that we continued working on it.”

BCT combines the CSA-cement technology with the classic OPC technology. In the case of calciumsulfo-aluminate (CSA), this means the rapid formation of ettringite with a high early strength. Thus, the use of this type of cement is not allowed in structural applications due to the reduced durability and thermal stability of ettringite. Belite (C2S), however, is characterized by a slow-reacting phase in OPC, which is responsible for the subsequent fatigue strength (after weeks and months). Belite forms in different modifications with different kinetics:

In 2010, the researchers at HTC started investigating the cement chemistry of BCT under various process conditions. Dienemann: “For the first time, we looked more closely at the ternesite clinker phase, which was considered to be non-reactive until now. This phase does not react with pure water, but if the pore solution contains aluminium, there occurs an immediate chemical reaction and a solid structure is formed.” After the first successful burning tests in the lab, HTC registered two patents for the manufacturing of clinker containing ternesite (Belite Calciumsulfoaluminate Ternesite – BCT) in the late summer of 2012, and four patents for applications using ternesite containing clinker in various binder systems (= cement types).

The advantages of ternesite containing clinker are obvious: Because of its chemical composition and manufacturing at lower temperatures, the new product generates up to 30 % less CO2 than normal Portland cement clinker. There is also an improvement in energy efficiency, as the burning temperature is 150 to 200 °C lower and the fuel consumption is reduced by about 10 %. The electricity costs for the manufacturing process are likewise lowered by about 15 %, because less energy is required, particularly for the grinding process.

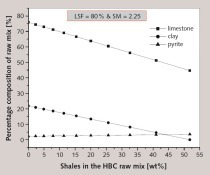

Dr. Wolfgang Dienemann (Fig. 3) describes the next steps at HTC as follows: “Since the addition of high-quality aluminium carriers such as bauxite is very expensive, we are currently experimenting in alternative trials with the addition of waste materials containing aluminium, e.g. brown coal fly ash and other slags. In addition, the use of other industrial by-products, such as FGD gypsum, could also be considered.”

The first large-scale trial is planned for this year at one of the German HeidelbergCement plants, where the new products are to be manufactured for the first time with the existing plant technology. ZKG will inform its readers about the progress of this trial.