Calcium Aluminate Cement for corrosion resistant sewer mortars and concretes

Microbiologically Induced Corrosion (MIC) causes severe concrete deterioration in pipelines, manholes and sewer structures. This process is caused by sulfuric acid producing bacteria which mainly occur in waste water systems. Mortar compositions containing Ordinary Portland Cements (OPC) and Calcium Aluminate Cement (CAC) have been selected for a MIC test. Workability and strength development of each mortar composition was determined prior to testing. Special prepared mortar cubes were then placed in an accelerated biogenic corrosion weathering chamber. Change in weight loss, specimen shape, surface pH and alterations of mortar cubes during 10-month testing were recorded. Different material properties regarding corrosion resistance between the two OPC mortars and the CAC mortar are evident.

1 Introduction

Sewage systems are used to collect the wastewater of cities and to transport them to sewage treatment plants. These systems are extensive and commonly made of concrete. Concretes and mortars used in pipelines and manholes of sewage systems are damaged by all kind of attacks (physical, chemical and thermal). MIC has been identified as the strongest form of degradation of concrete sewage systems worldwide and is caused by sulfuric acid producing bacteria from the genus thiobacillus and others, that grow in environments on concrete surfaces which offer favorable conditions (e.g. available water, low pH, hot climate). MIC leads to replacement of sewage structures before time and additional costs of $500 billion are estimated for the next 20 years to keep existing wastewater structures functional. At the same time, the replacement of old damaged sewage systems must consider a target approach choosing the correct materials to produce the concrete elements or mortars that will be exposed to MIC. Figure 1 shows the schematic mechanism of MIC corrosion and an example of severe sewer corrosion.

The activity of biofilm on the substrate of cementitious material, produces sulfuric acid that diffuses into the concrete and reacts with the concrete or mortars. The conditions between the top layer and the inner layer change greatly and are characterized by a large pH gradient. At pH <3 gypsum (C$2H) is formed and remains stable. Gypsum can react with calcium aluminate hydrate and form ettringite. As a result, ettringite is pres-ent in the inner parts of concrete where pH remains higher (>4). With the continuing increasing sulfuric acid amount, pH values decrease also in the inner part of the concrete and transform ettringite into gypsum accompanied by volume expansion of the structure. This causes concrete cracks, creates higher porosity and a higher specific surface of the substrate.

Considerable researches have examined biodeterioration of concrete structures by living organisms, including underground structures, sewage- and wastewater treatment systems. CaO content makes the OPC very sensitive to sulfuric acid attack, due to its Ca(OH)2 which is soluble in acids. More-over, due to the fact that metabolism of bacteria is highly dependent on pH conditions, the neutralization capacity of the concrete is an important factor and determined by the calcium- and aluminum contents, both of which have the capacity to neutralize acid. Calcium dissolves at all acidic pH values:

Ca(OH)2 + 2H+ → Ca2+ + 2H2O or

CaCO3 + 2H+ → Ca2+ + H2O + CO2

Calcium aluminate cements contain less calcium, are Ca(OH)2 free and form a metastable and stable calcium aluminate hydrate phase. CACs have a lower neutralization capacity than OPC above pH 4 but the insoluble alumina gel can form a protective layer. CACs have a higher neutralization capacity below pH 4 due to the dissolution of the alumina hydroxide.

Al(OH)3 + 3H+ → Al3+ + 3H2O

Moreover, CAC creates locally a barrier layer which slows down the rate of corrosion and Al3+ inhibit the bacterial activity [1, 2].

The present study targets the MIC resistance evaluation of CAC containing mortar in comparison to different OPC mortar mixes. All mixes have been subjected to an accelerated MIC laboratory test method with real sewer bacteria. Changes in weight of the test specimens, measures of pH and mass loss were used to evaluate the physical degree of de-terioration and the chemical change in the mortar.

2 Experimental

2.1 Raw materials and mortar mix design

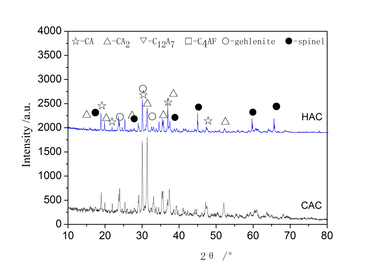

CEM I 52.5 R –OPC cement and CEM III/B 42,5 N-LH/SR/NA were chosen as reference to a CAC containing ~45 % Al2O3 (brand name: ISTRA 45). Table 1 shows the chemical composition of the raw materials.

Three different mortar mixes were chosen for testing the binder systems against MIC corrosion (Table 2). All mortars have EN 14647 mortar composition and contain different cements and 0-2mm CEN quartz sand. Plasticizer was used for both Portland cement mixes to get reasonable flow with W/C ratio = 0.35. Mixes CEM I and CEM III are considered as a reference to the mix containing CAC 45. Furthermore, CEM I and CEM III are taken as an example for the whole bandwidth of EN 197 OPCs ranging from a high clinker amount to a high GGBFS (Ground Granulated Blast Furnace Slag) substitution in OPC.

2.2 Mortar preparation

All mortar mixes were prepared according EN 196-1 and cast into 4 x 4 x 16 cm prisms. Mortar workability was determined at a shock table at 30 min. according EN 1015-3. Compressive strength was determined after 38d at 20°C and 98% RH according to EN 196-1. 8 cubes with 2 cm edge length were cut out of each prism set after 38d and dried for 3d at 50°C as initial sample conditioning for the microbiologically induced corrosion chamber tests.

2.3 Accelerated MIC test

The test facility used for the weathering was operated by Fraunhofer Umsicht, Germany [5] and leads to accelerated weathering because of the optimized bacteria growth conditions regarding H2S concentration, nutrient content, moisture, and temperature. Acceleration factor of this experimental setup for concrete samples is in the range of 8-10. This means that a 6 months period in the chamber is comparable to a 48 up to 60 months period in a real sewer system. Figure 2 show the corrosion chamber setup.

Bacteria from a real sewer were taken and grown as mass cultures in the laboratory, harvested, and sprayed as an aerosol onto the samples. Inoculation was carried out by beginning with moderately acidophilic strains and followed by strong acidophiles. Finally, an environment on the sample surface was established in which the microorganisms consume mainly solubilized hydrogen sulfide and generate a pH range of 0 to 1. The pH values of the sample surfaces were weekly determined throughout the test period using a surface pH meter or pH test stripes in the case of unstructured surfaces. Mass change of cube-shaped samples was carried out by double determination of weight measurements combined with living cell count determination of the following five bacteria species: moderately acidophilic sulfur oxidizing bacteria (MOT), strongly acidophilic sulfur oxidizing bacteria (SOT), chemoorganotrophic bacteria (COT), strongly acidophilic iron oxidizing bacteria (FeOx) and fungi. The remaining fragments were dried and finally weighed. By these the mass mt of a selected cube at the sampling time t is obtained. Table 3 summarizes the experimental conditions of the MIC setup.

Mass change mc was calculated by using equation (1), with the dry weight m0 determined measured before starting the weathering campaign.

mc = (mt – m0)/m0 x 100 [wt.-%] ⇥(1)

3 Results and discussion

3.1 Mortar mechanical and analytical test results

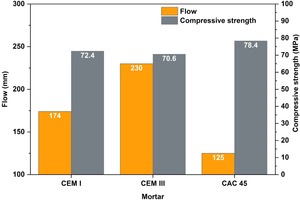

Figure 3 displays 30 min. flow and compressive strength results of the three mortar mixes. OPC mortars CEM I and CEM III show good workability because of the plasticizer used for these mixes. The mix containing CAC 45 has the lowest flowability after 30 min. indicating a stiff mortar mix design which results in perfect properties for a shotcrete application in the sewer. Mixes containing OPC show high compressive strength of around 70 MPa after 38d. CAC 45 mortar has with 78.4 MPa the highest compressive strength of all mixes even with a W/C-ratio 0.40.

3.2 Biogenic sulfuric acid corrosion results

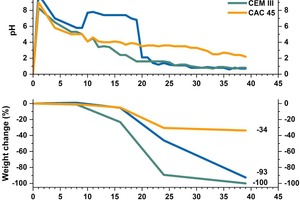

pH-value evolution and weight change of the specimens under biological attack are displayed in Figure 4. All mixes show initial pH between 8 and 10 after one week. OPC-based mix CEM I stabilizes at pH 6 between week 4 and week 9 and then rises and stabilizes at around pH 7 until week 20. Subsequently, the pH value sharply drops to pH 2 and decreases to pH < 1 until the end of the study. CEM III mortar shows a constant decrease of pH starting from week 1 until the end of the study. The mix containing CAC 45 reaches a surface pH of around 4 until week 16. Its surface pH remains stable until week 30 and then slightly decreases to pH > 2.

No corrosion by means of mass loss is detected in all samples after 8 weeks of exposure. CEM III has the highest mass loss after 16 weeks whilst all other mixes have a mass loss < 20 %. CAC 45 mix has the lowest mass loss after 24 weeks. After 39 weeks of exposure, CEM I and CEM III are severely affected by corrosion. pH evolution confirms CEM I and CEM III cannot buffer the acid produced by bacteria and therefore the pH value decreases. Both OPC mortar mixes seems to buffer the system for the first months, but pH drops down to 1 at the end of the weathering cycle. Mixes containing OPC show no high weight loss till week 16 but start to be strongly affected by corrosion after 24 weeks. The presence of CaO in the mixes containing OPC promote acid attack and gypsum formation is observed at the surface.

Mix CAC 45 contains Calcium Aluminate Cement and has the lowest mass loss of all samples. The better buffer capacity by means of pH values confirms the higher biogenic corrosion resistance. Whilst the pH of OPC-based mixes descends to around 1, CAC 45 mortar stabilizes between pH 2 and 4. The CAC substrate inhibits bacteria colonization, thus limiting sulfuric acid production. Furthermore, pH stabilization indicates the protective role of hydrous alumina gel layer.

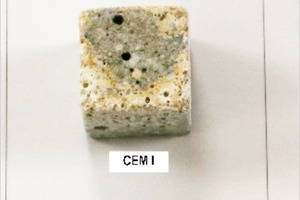

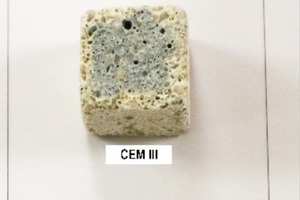

Table 4 displays the CAC 45 and CEM III mortar cube after 39 weeks of testing, directly after removal from the corrosion chamber.

CEM III mortar cube is completely disintegrated by expansion and cracks. The OPC matrix has completely transformed into gypsum whereas the CAC 45 mortar has only slight biogenic corrosion on its surface and is in cubic shape.

Table 5 displays the mortar cube evolution for 39 weeks. All samples have been washed and loose parts have been removed. The removed parts consist of quartz sand and gypsum.

Specimens containing OPC have been completely disintegrated whilst CAC 45 mortar specimens keep their original shape even if they suffer from mitigate biogenic sulfuric acid corrosion attack. The visual inspection reveals also that mortar mixes containing OPC are covered by gypsum which is visible after 16 weeks of exposure. Again, the complete binder matrix of CEM I and CEM III was transformed into gypsum after 39 weeks in the corrosion chamber.

After 8 weeks of exposure almost all the tested specimens showed high numbers of moderate acidophilic Sulphur Oxidizing Bacteria (MOT) beside moderate to high cell counts of strongly acidophilic SOB (SOT). Sample surface pH value was already lowered to minimal 3.6 due to the metabolic activity of the acid producing microflora. A significant decrease in colonization of the samples by the moderately acidophilic MOT was noted at the end of the exposure after 39 weeks except for the mix CAC 45 which remained apparently undamaged.

The decrease in cell numbers is in accordance with the surface pH drop down to 0.6 which is toxic for the MOT and causes the destruction of the alkaline cement matrix. At this stage, more acid resistant microorganisms like fungi and strongly acidophilic sulfur oxidizer dominate the population on the sample. Specimen with CAC 45 remain almost completely intact and cell counts of the inoculum have not been substantially lowered. After 39 weeks of testing, weathering led to different damage patterns. Most severe MIC attack is observed on the CEM I and CEM III specimens which were completely dissolved or disintegrated into small pieces, mainly acid resistant quartz sand covered by gypsum remains. These specimens exhibited the lowest pH values on the surface (pH 0.6 – 1.0). In contrast, CAC 45 mortar remains intact.

4 Conclusions

Based on the results of this investigation, a proper binder matrix must be considered and tested prior to application for long lasting durable sewer mortars and concretes. Weight loss alone as an indicator for microbiologically induced corrosion resistance can give misleading results since gypsum remains in the system and might compensate for the binder matrix weight loss. Portland cements CEM I and CEM III used in this study offer very good workability and mechanical strength whilst having poor MIC resistant properties. CEM III even seems to perform worst in the test because of low clinker amount in its composition, thus having low pH buffer capacity. On the other hand, CAC mortars and concretes have excellent MIC resistant properties. The workability of the CAC 45 mortar indicates its suitability for dry shotcrete applications for wet wells, access chambers, manholes and pipes. Its mix design can be adapted to other mortar placing conditions.

Therefore, a holistic approach which takes into consideration raw materials, fresh and hardened concrete proprieties together with the microbial processes needs to be considered when designing the mortars and concretes for sewage systems.

//www.calucem.com" target="_blank" >www.calucem.com:www.calucem.com

This article was first published in Drymix Mortar Yearbook 2020, Munich, 2020, ISBN 978-3-9821114-1-4

![1 Mechanism of MIC corrosion [3, 4, 5] and example of a corroded sewer system](https://www.zkg.de/imgs/1/6/0/1/2/7/6/tok_a966031e079e56217be51ecf93cc7056/w300_h200_x557_y315_Materials_Calucem_CAC_Figure_1a-b0c6bb7eba1e5849.jpeg)

![2 Fraunhofer Umsicht MIC corrosion chamber schematic drawing (left) and installation (right) [5]](https://www.zkg.de/imgs/1/6/0/1/2/7/6/tok_153174cdf167f05ef3c55ba67d5c57f4/w300_h200_x503_y360_Materials_Calucem_CAC_Figure_2a-fec1b85448051e6c.jpeg)