Fine material synergetic calcination type rotary kiln

graded calcination system

(22) 23.10.2019

(43) 30.04.2020

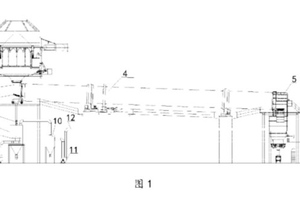

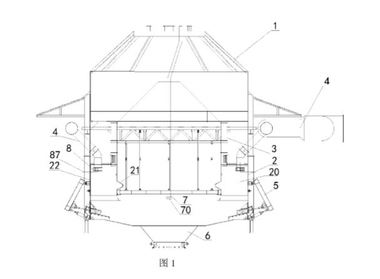

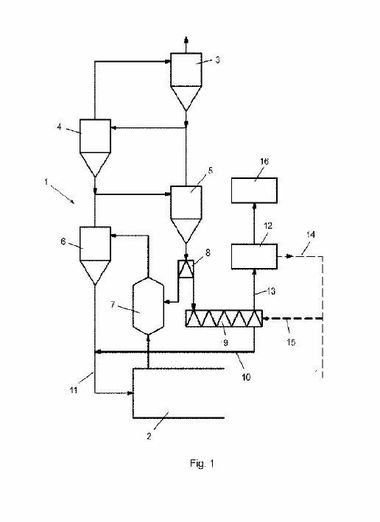

(57) Disclosed is a rotary kiln graded calcination system for the co-calcination of fine materials, the system comprising a pre-heater (1), a transfer chute (2), a rotary kiln (4), a kiln head vertical cooler (5), a fly ash cooling compartment (7), and a graded discharge device (3), wherein the graded discharge device (3) is located in the transfer chute (2) and configured for screening for fine materials and coarse materials, such that the fine materials enter the fly ash cooling compartment (7), and the coarse materials enter the rotary kiln (4) to continue calcination. The rotary kiln graded calcination system facilitates the alleviation of ring formation in a rotary kiln shell while guaranteeing the lime calcination quality.

(71) Jiangsu Zhongshengyuan Technology Co., Ltd., Jiangsu (CN)