Method of extracting vanadium by countercurrent acid leaching of clinker from calcining firing

(22) 27.11.2019

(45) 26.08.2020

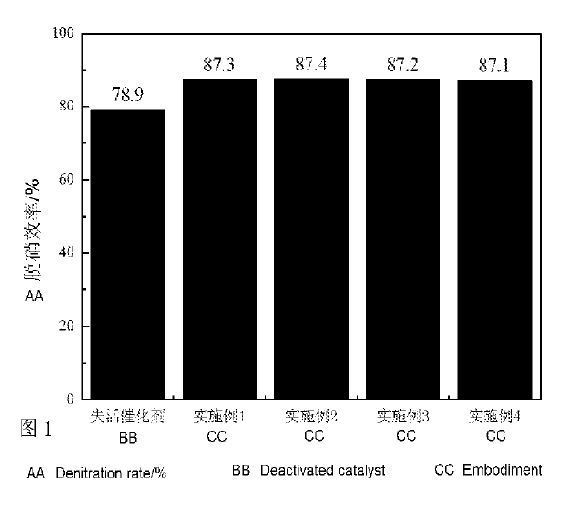

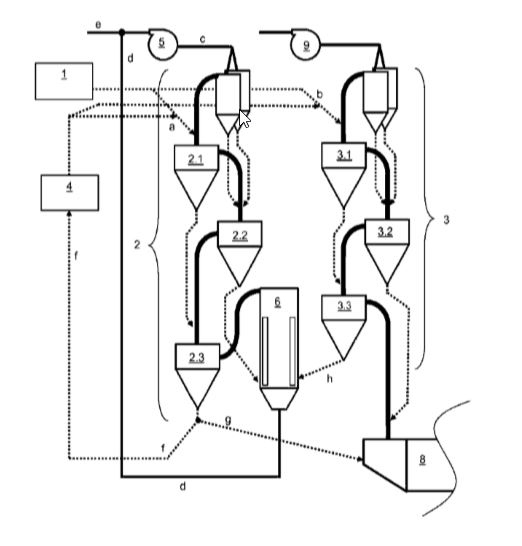

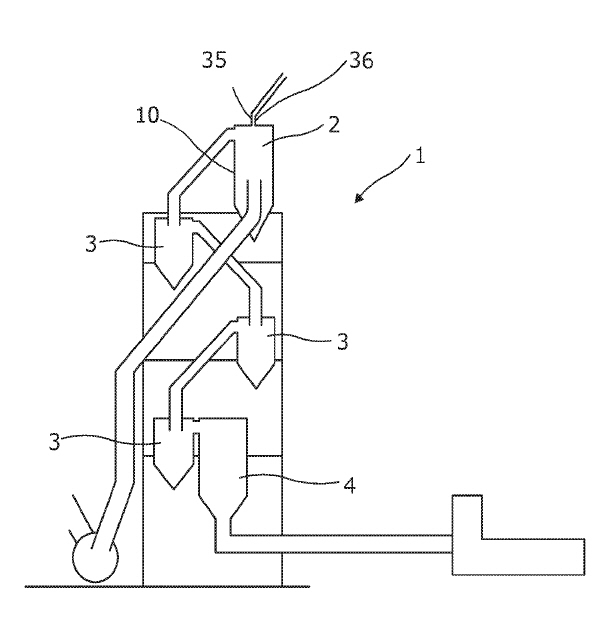

(57) Field: chemistry. Substance: invention relates to vanadium extraction technology, in particular to a method of extracting vanadium with countercurrent acid leaching of clinker, obtained as a result of calcining roasting. Method of extracting vanadium by countercurrent acid leaching of clinker, obtained as a result of calcining roasting, includes the stages: a. first leaching stage, on which clinker obtained as a result of calcining roasting is mixed, with a leaching liquid, adding sulphuric acid for the first leaching step, adjusting the pH value of the system at the first stage of the leaching process in range of 2.8 to 3.5, separation of solid phase from liquid to produce leach from first leaching stage and solid phase after leaching and washing solid phase to produce filtrate from first stage and solid substance; b. the second leaching stage, at which solid substance washed at stage a. is mixed with fluid for leaching at control of pH value of final system at the second leaching stage in range from 1.8 to 3.5 and separating solid phase from liquid phase to produce leachate from second leaching step and solid substance; c. third leaching stage, on which solid substance, leached and separated at stage b., mixed with a leaching liquid, which is represented by recycled water obtained after neutralization of waste water with lime or after electrolysis of waste water with a pH value of 0.7-1.5, when controlling the pH value of the final system at the third leaching stage in range of 1.4 to 2.2, separating the solid phase from the liquid phase to obtain leachate from the third leaching step and solid substance, and then washing the solid substance to obtain a filtrate from the third step and tailings after extraction of vanadium. Effect: method provides high rate of extraction of vanadium by leaching.

(73) Pangang Group Research Institute Co., Ltd. (CN)