Modelled fate of sulphur and chlorine

in rotary lime kilns | Part I: Chemical equilibria prevailing

in the kilns

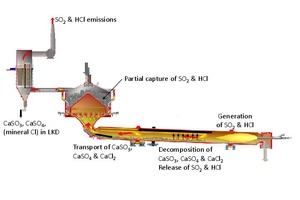

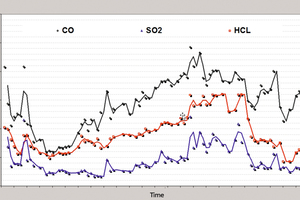

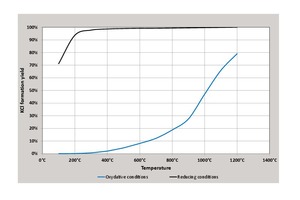

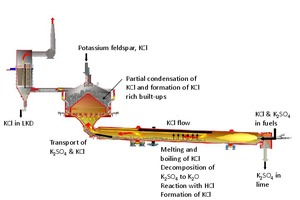

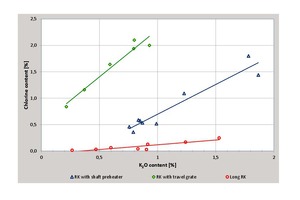

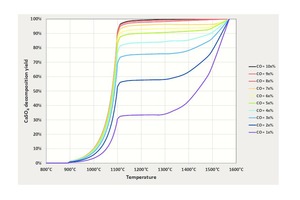

Investigations performed to predict the SO2 and HCl emissions of rotary kilns have shown that Investigation performed to predict the SO2 and HCI emissions of rotary kilns have shown that the chemical reactions needed to assess these emissions also enable quantification of the generation rate of build-ups in the preheating zone of these kilns. As anticipated by the theory and confirmed by industrial tests, sulphur and chlorine loops were found. The chlorine loop is closely interconnected to the sulphur loop that is itself influenced by the process conditions prevailing in the kilns. The quantification of the thus resulting emissions and generation of build-ups requires a precise assessment of all reactions involving sulphur and chlorine. However the first results of the modelling showed only a fair agreement between calculations and monitoring results. Further investigations were therefore carried out. Accordingly it was found that potassium plays a key role in the chemical reactions occurring in rotary lime kilns. The inclusion of this element in the modelling enabled a significant increase in the accuracy of the prediction. This paper presents the chemical reactions used in the model.

1 Introduction

The lime industry is using rotary kilns especially for the flexibility of this production tool. The energy efficiency of rotary kilns was along the time improved, especially with the development of shaft or vertical preheaters.

Practical experience shows that operators of rotary lime kilns face several challenges:

Rotary kilns equipped with vertical preheaters have to be frequently stopped since the preheaters are clogging for reasons that were until now unexplored and often considered as unavoidable. These stops trigger operational costs (cooling down of the kiln, cleaning of the...

![6 HCl capture by CaO or CaCO3 at different temperatures according to [7]](https://www.zkg.de/imgs/1/2/9/7/6/1/3/tok_d0eb568c0142ec179185b345839aacb4/w300_h200_x360_y270_Figure_6-4f85c50e5c83b9e4.jpeg)