Proven experience with alternative fuels in the cement kiln process

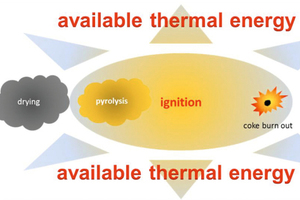

In times of increasing energy costs, it is of vital interest for any company to save energy. To cut the energy costs for clinker production, the German cement industry started substitution of primary fuels with Alternative Fuels (AF) such as used oil or tyres after the first oil crisis of 1973. Today, alternative fuels and raw materials (AFR) include a wide range of types of hazardous and non-hazardous waste, as well as solid and liquid, organic and mineral waste.

1 Introduction

To cut the energy cost for clinker production, the German cement industry started substitution of primary fuels with Alternative Fuels (AF) such as used oil or tyres after the first oil shock in the early 1970s. Today, at more than 2 €/GJ energy costs and after establishing a reliable disposal management, alternative fuels and raw materials (AFR) include a wide range of types of hazardous and non-hazardous waste, as well as solid and liquid, organic and mineral waste, which have to be pre-processed, quality-monitored and tailor-made for existing kilns or newly-installed kilns and...