Simulation of limestone calcination in normal shaft kilns –

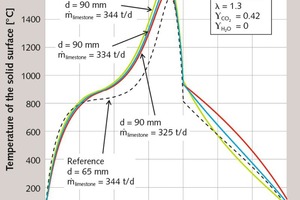

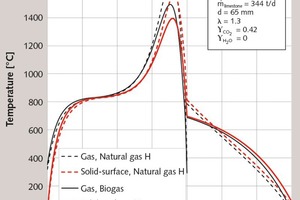

Part 2: Influence of process parameters

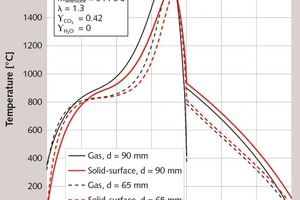

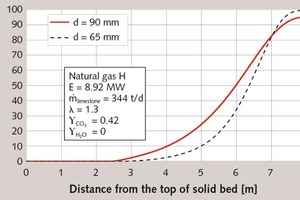

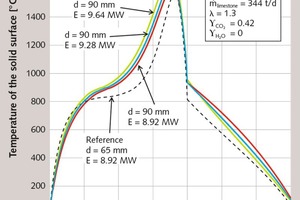

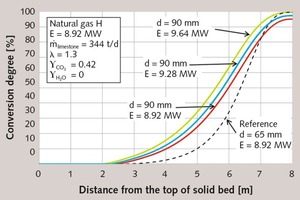

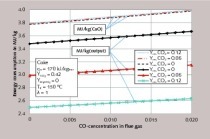

For normal shaft kilns it is described how the axial profiles of the surface and core temperature of the stones, their decomposition and the gas temperature depend on the process parameters, which are stone size, energy input, throughput and type of fuel. In addition, the influence of these variables on the specific energy consumption, the residual CO2 content and the pressure drop is discussed.

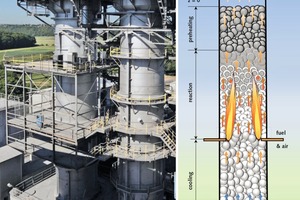

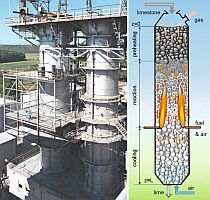

1 Introduction

The calcination of limestone in normal shaft kilns is a complex process, since it is influenced by a variety of parameters. These influencing factors are:

the operating variables such as energy input, throughput, type of fuel, air flow,

the kiln parameters such as diameter, packed bed height, cooling zone length,

the limestone parameters such as mean particle size and material properties (thermal conductivity, coefficient of decomposition, decomposition pressure, calcite fraction, magnesite fraction, humidity, etc.)

ambient conditions (ambient temperature, air velocity, clouds).

The...