Tuning the availability for drivetrains of cement mills

Vibration diagnosis makes it possible to detect the smallest irregularities in gearboxes and rolling bearings at an early stage. These irregularities can include damage to rolling bearings, gears and shafts, imbalance and misalignment. The operator of machines with mechanical drives thus obtains status information that makes it easier for him to plan maintenance and protect him from unplanned downtimes.

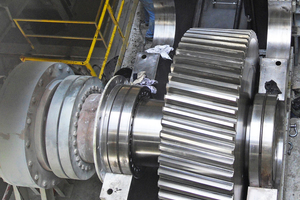

Drivetrains on cement mills generally have to be available around the clock for 340 days a year. In addition to the quality of the drive itself, maintenance has a major influence in meeting this expectation. Of course, every operator would like rolling bearings and gearboxes to work without problems for years until they have reached their projected service life (Figure 1). However, many influencing factors mean that some drive elements cannot reach this point in time, even with optimal care.

In order to meet the specific availability expectations, it should be known what happens to the drivetrain and which components will have used up their wear and tear at what time. But the level of wear and tear does not decrease linearly. The annual view through the inspection hole is usually not enough, especially since rolling bearings are not visible at all. Therefore, tools are required that provide current, reliable status information at least every few days.

Condition monitoring by vibration diagnosis

Vibration diagnosis has become the method of choice in the past 60 years. Vibrations contain a lot of information, especially about mechanical phenomena. Vibrations also spread very well and are easy to measure and interpret.

If, for example, the raceway of a rolling bearing has an error, each rolling element that passes this point generates an impact. The frequency, i.e. how often the impacts are generated per second, results from the internal rolling bearing data and the speed. Defects on gearwheels are similar. Specific vibrations are generated that can be precisely assigned to a mechanical cause based on the frequency. Thus, based on a few rules, the vibration signal can be used to draw clear conclusions about the damage condition of a drive.

The measurement is usually carried out with piezoelectric acceleration sensors. These are sufficiently precise and cover a very large measuring range. They are also robust, easy to install and inexpensive.

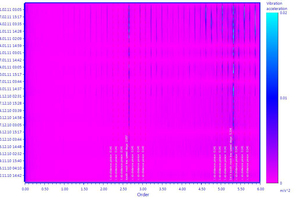

The vibrations are made visible in the spectrum and in the envelope curve spectrum. And because modern drives are often operated at variable speeds, the order spectrum and the envelope curve order spectum are used instead. All of these spectra are formed in modern systems with high resolution, so that vibrations can be measured very finely, that is, down to a few millihertz. This accuracy is necessary, on the one hand, to reliably analyze defects and, at the same time, to reliably avoid misinterpretations.

The spectrogram in Figure 2 shows that the amplitudes of certain frequencies of the oscillation increase with time. Before that, by simple calculation it was checked that these frequencies are damage frequencies. From the concrete progressive amplitude course a critical damage course has to be concluded, which sooner or later requires the replacement of the damaged parts. At this stage of the damage, however, there is still enough time to prepare the repair, to organize spare parts, hoists and repair personnel and to plan a temporary standstill.

More scope for decision-making during repairs

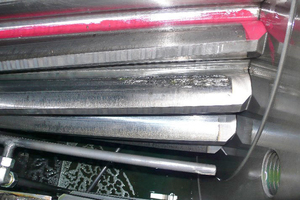

The damage that was visible after the gearbox was opened finally confirms the result of the vibration diagnosis (Figure 3). Although the extent of the damage was not yet a reason for shutdown, it was significant pre-damage that would have resulted in a total breakdown of the gearbox. Thanks to the timely detection of the damage, it was possible to produce at full capacity until the repair date.

Condition monitoring therefore leads to an immense increase in availability, from which the plant operator benefits directly. The cost of such a system, however, is very low.

The Peakanalyzer, GfM‘s online condition monitoring system, monitors the vibrations on any number of sensors fully automatically and without human intervention (Figure 4). The vibrations are measured and analyzed every few minutes. An alarm is only given when there is concrete evidence of possible damage. Only then a responsible person is asked to make a competent maintenance decision. As a rule, the drivetrain will then continue to be operated, but the condition will be monitored more precisely and repair activities can be prepared without hurry.

//www.maschinendiagnose.de" target="_blank" >www.maschinendiagnose.de:www.maschinendiagnose.de