The core of the Cement Process

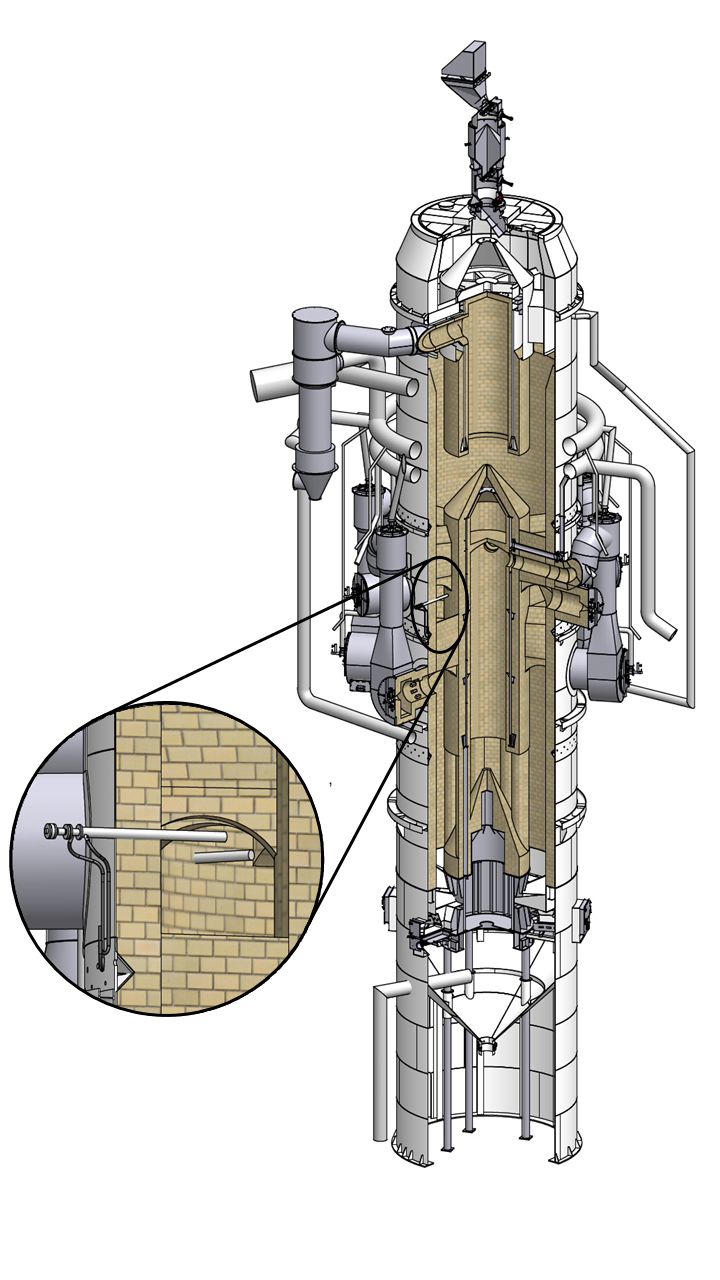

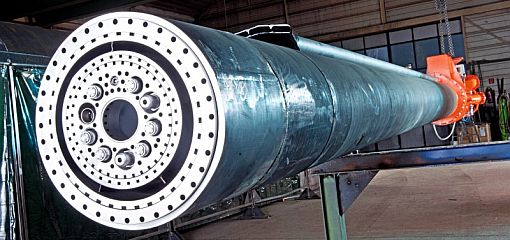

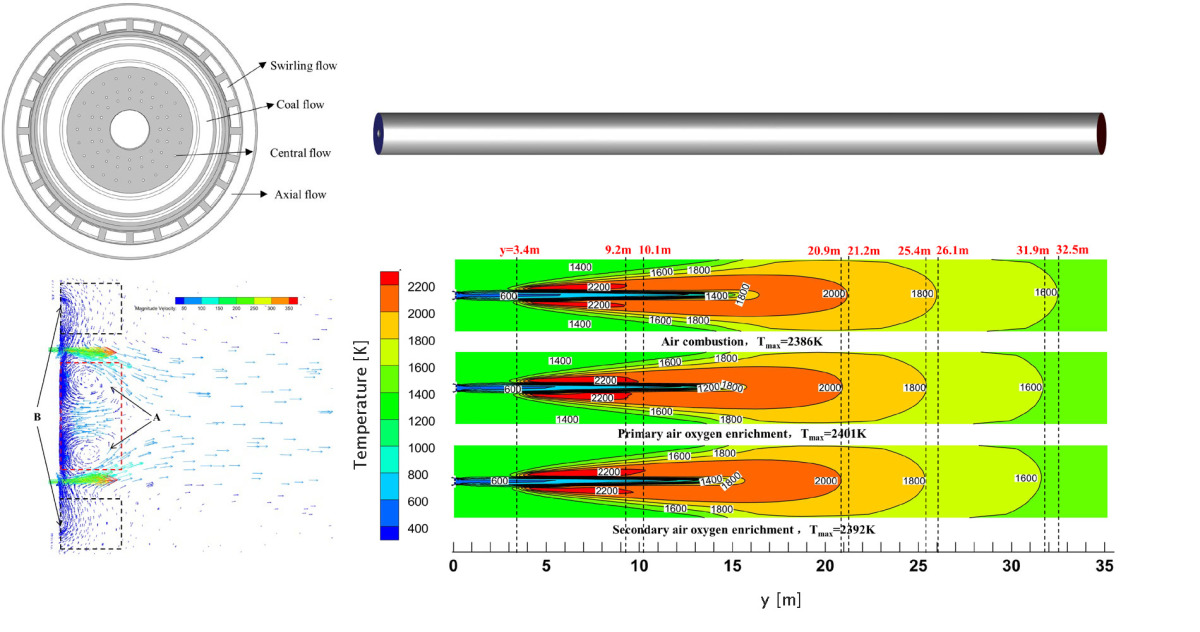

The process of clinker manufacture has evolved massively over the last decades. Back in 1843 when William Aspdin invented the technical process of clinker manufacture in a rotary kiln, the production was primarily driven by the burner. With all the developments coming in the subsequent years, especially the precalciner and the external combustion chambers, the main burner (as it has been called since then) only takes over about 45% of the thermal input. Still the main burner largely defines the quality of the product and remains to be an important piece of equipment in the clinker manufacturing process. Many smart engineers are constantly working to further improve the burner technology to accommodate new requirements regarding emissions reduction and ability to burn alternative fuels. Implementing technologies from other industrial applications has proven to be difficult, because in the cement industry the burner is an integral part of the kiln process and operates with only a small portion of primary air through the burner itself. Conventional low-NOx-technologies of other industries don’t apply. Satellite tubes for higher feed rates of alternative fuels demonstrate this characteristic of integral burner-and kiln-system even more. So what can be the future developments for the burner technology? Will we be able to convert the “burning” into direct electric heating? Will it be possible to operate rotary kilns with plasma burners and come to CO2-free kiln exit gases? The engineers of the cement industry will surely find ways to further improve the “core of the clinkering process”!

Yours sincerely

Matthias Mersmann