Method and device for treating and utilizing bypass dusts

(22) 20.05.2016

(43) 31.05.2018

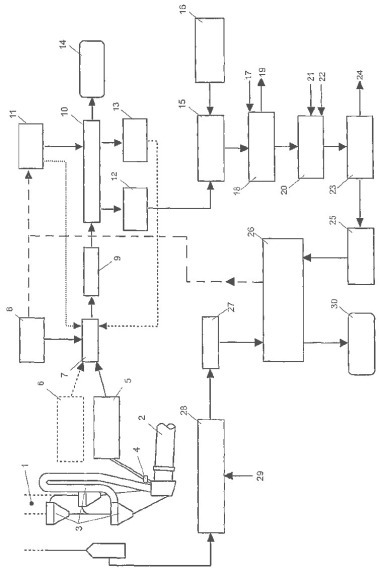

(57) A method for treating and utilizing bypass dusts from a cement production process involves a) contacting the bypass dust with an aqueous phase and mixing the same to obtain a suspension, wherein water-soluble components of the bypass dust are dissolved in the aqueous phase; b) performing a solid/liquid separation, in particular a vacuum filtration or a filter press filtration, to separate the solids contained in the suspension, wherein a brine remains; c) precipitating a partial amount of the heavy metals present in the brine, and optionally Ca, and separating the precipitate from the brine; and d) subjecting the brine to an electrocoagulation, wherein a flocculate containing the heavy metals remaining in the brine is separated.

(71) Holcim Technology Ltd., Jona (CH)